Author(s): Paul B McNulty

Automation in Food Production has attracted the global attention of researchers, equipment suppliers and farmers. Universe Optics, machine vision specialists, have observed that: Large farms (1,000 acres or more) started the trend, adopting the tools of precision agriculture-using GPS-guided tractors, drones, and computer modelling to customize how each inch of land is farmed [1-3]. Farm managers can measure and map things like soil acidity and nitrogen levels, and then apply fertilizer to specific plants-not just spray and pray.

Automation in Food Production has attracted the global attention of researchers, equipment suppliers and farmers. Universe Optics, machine vision specialists, have observed that: Large farms (1,000 acres or more) started the trend, adopting the tools of precision agriculture-using GPS-guided tractors, drones, and computer modelling to customize how each inch of land is farmed [1-3]. Farm managers can measure and map things like soil acidity and nitrogen levels, and then apply fertilizer to specific plants-not just spray and pray.

In contrast, Geert Hekkert, Editor, Future Farming, has observed that: Asian countries - with China in the lead – are more relaxed about the application of new technologies such as spray drones in farming [4]. In the EU … spraying is allowed … but only with approved and tested sprayers driving in the field … because of the high risk of drift … the same applies to other new technology such as autonomous field robots and tractors … where … strict Western regulations with regard to safety and security are preventing a faster breakthrough … Shortly afterwards, 22 May 2020, Hekkert, noted the prevailing dynamism in the sector: that sales of drones are set to rise in the USA, probably, on foot of new regulations that now permit drone Applications, as well as in China and India, even though concerns about spray drift still remain.

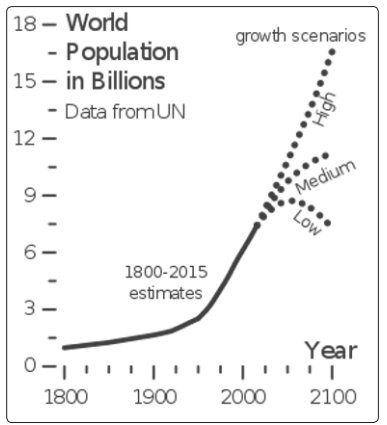

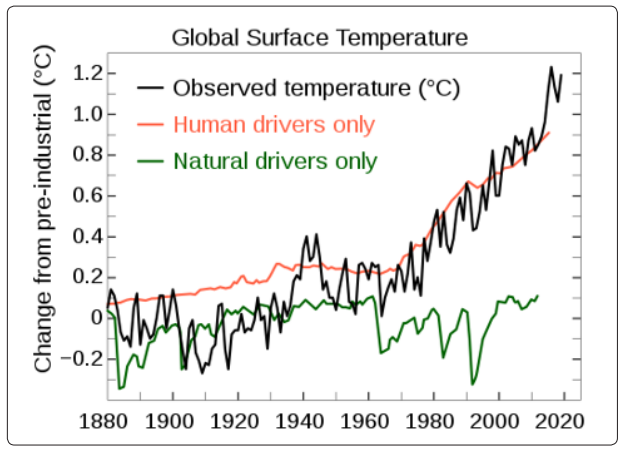

I have reviewed some recent trends in food production, automation and robotics as reported in popular magazines including Future Farming whose web editor, Hugo Claver, has supported my endeavor [5,6]. The trends covered may be of interest to a broad readership. These new technologies are driven by the unavailability of skilled human labour as urbanization continues to drive rural youth into the towns and cities. The consequential reduction in skilled labour makes the outlined technological advances more attractive to farmers and growers on whom we depend for our food supply. Even more pressing is the global population estimated as 10.8 billion in 2020, and projected to rise to 11.0 billion in 2100 (Figure 1.) The food necessary to feed these extra 0.2 billion (i.e. 200 million extra people) has to be produced against a background of diminishing skilled labour, recovery from the current Coronavirus epidemic and the continuing struggle against Global Warming (Figure 2) that threatens to diminish crop yields [7-9]. More recently, the prospect of a revived Dust Bowl in the Great Plains is yet another issue to be confronted.

Figure 1: UN projected world population

Figure 2: NASA observed temperature vs the IPCC 1850-1900 average used as a pre-industrial baseline. The primary driver for increased global temperatures in the industrial era is human activity, with natural forces adding variability.[8]

In these circumstances, the automation and robotization of food production will be crucial to the challenge of meeting the nutritional requirements of a growing population, whose life expectancy will increase, as living standards improve in neglected pockets of humanity. My objective is to demonstrate that significant progress has been made in food production systems including those concerned with autonomous (self-driving) or electric tractors (tillage); autonomous robotic implement carriers; autonomous robots and drones (seeding, weeding, fertilizing); electric weed killers; combine harvesters; robotic milking and harvesters as well as carbon sequestration. Among the developed nations, Japan also has to cope with a declining national as well as rural population forcing them to expedite a transition to an automated and robotized food production system. A recent article by Matt McIntosh “Pandemic Highlights Automation Gaps …” outlines the case for an increasing emphasis on Automation in the midst of Covid-19 [10]. Interestingly, lower air pollution during Covid-19 may have improved Crop Production. Some preliminary conclusions may be drawn from ongoing research chapters to date that will be published in a book on the current topic in due course:

Diesel-fueled Tractor Systems are an obvious starting point for carbon emission abatement given their seminal position in farm mechanization systems. Japan is leading the race to eliminate diesel emissions with electric power through their advanced position in automation and robotic research as manifested by the Kubota Autonomous Concept X Tractor, a 45 kW (60 hp) electric model costing about 50% more than its conventional counterpart (Figure 3.)

Figure 3: Kubota Autonomous Concept X Tractor

Operating exclusively with electrically charged batteries bear the potential to revolutionize food production through their utility in crop scouting, spraying and fertilizer applications thus side-lining fossil fuels and promoting sustainable food production. But tilling the soil and harvesting the crop will still require replacement of diesel engines with electric motors.

Recent adoption of robotic milking in Ireland and further afield will contribute to the reduction in carbon emissions in dairying by reducing milking time by about 50% with a concomitant reduction in carbon emissions (Figure 4.)

Figure 4: Lely’s Astronaut A5 milking robot

Many delicate leafy greens and soft fruits and vegetables have remained largely resistant to robotic picking. However, root ai has developed Virgo whose cameras maneuver the Robot along greenhouse rows. Computer vision processes the quality and ripeness of each tomato. Sensors enable Virgo to DISTINGUISH BETWEEN FRUITS, leaves and vines. The plastic picker is three- fingered. A robotic arm extends the gripper to the tomato which it gently clasps then spins the tomato free with a quick, flick-of- the-wrist-style motion and deposits it into one of several storage shelves built into the mobile robotic unit thus reducing labour requirement with concomitant reduction in carbon emissions (figure 5.) Interestingly, the recent winner of The Best Field Robot Concept Award 2020 was an Israeli Tevel Aerobotics fruit picking drone.

Figure 5: T-6 robotic harvester gently handles strawberries to avoid bruising and fruit damage.

Wageningen University and Research Centre has launched its 2020 Farm of the Future project in which monoculture will be replaced by strip cropping supported by robots, drones and precision technologies with minimal use of artificial fertilizer and crop protection products [6]. https://www.wur.nl/en/project/Strip-cropping.htm (2.36 min.) The experimental project provides crop rotations of: grass clover – cabbage – onion – potato – wheat and carrots using three crop pairs: cabbage – wheat, carrot – onion, and potato – grass clover, in which strips (3m wide) of the crop combinations are grown as mono-crops.

Experimentation will involve Wageningen’s autonomous tool carrier, the Danish Agrointelli Robotti not only for hoeing and weeding but also soil cultivation, sowing, crop care and possibly harvesting [6]. Drones will be used to identify diseases and pests whose images have been identified by Artificial Intelligence requiring 5G for the drone to act swiftly in milliseconds. The system will need to be simple so that the farmer can control his ROBOT and drone through his smartphone (Figure 6.) Desirable outcomes of strip-cropping and the use of a field robot and drone include reduction of soil compaction, more resistant crops, enhanced biodiversity, enhanced perception of the landscape, and increased farm income [8].

Figure 6: Experimental strip-farming at Wageningen, Netherlands