Author(s): Himanshu Ramesh Lamba* and Lakhwinder S Hundal

Solid waste composting processes can produce unpleasant odors. The duration of composting varies from two weeks to a year based on material composition, pile size, and turning frequency. This research investigates the potential of a chemical-free biological approach to mitigate compost pile odors. Odor reduction was assessed through staff interviews, concluding that biological solutions offer a human-friendly option for odor control in large-scale waste composting facilities.

Increased population urbanization and rising demands have led to massive waste generation globally. The amount of waste produced is directly linked to the human population, creating challenges for large cities. Today, there is a growing concern regarding solid waste management among government authorities, environmental policymakers, NGOs, and waste managers, regarding the negative impacts of improper waste management practices. Developing countries, especially India, face a critical situation with municipal solid waste (MSW) prevalent in urban and semi-urban areas. Stockpiles of solid waste are prevalent in all major cities in India. The task of implementing eco-friendly MSW management in India is complicated by population growth, rapid and irreversible urbanization, and industrial development [1].

Table 1: Per Capita Municipal Solid Waste (MSW) generation in Indian cities [2].

| Population Range | Waste Generation Rate (kg per capita per day) |

|---|---|

| Cities with a population <0.1 million (eight cities) |

0.17-0.54 |

| Cities with a population of 0.1-0.5 million (11 cities) | 0.22-0.59 |

| Cities with a population 1-2 million (16 cities) | 0.19-0.53 |

| Cities with a population >2 million (13 cities) | 0.22-0.62 |

The per capita Municipal Solid Waste (MSW) generation in India varies, ranging from around 0.17 kg per person per day in small towns to approximately 0.62 kg per person per day in cities [2].

Among various waste processing methods, composting is considered a robust choice due to its capacity to sustain and rejuvenate soil fertility, as well as its capability to convert waste into a valuable resource.[1] Composting is a microbial-driven process turning organic waste into compost, but it often leads to undesirable odors affecting both compost quality and the environment. These odors, comprising ammonia, volatile organic compounds, and hydrogen sulfide, etc. can harm human health [3]. Factors like pH, temperature, and aeration influence odor emission during composting [4].

Microbial VOCs are the main cause of odors in compost facilities, detectable at levels below harm to human health. Different types of VOCs contribute to specific smells, such as rotten egg for sulfur compounds, vinegar for fatty acids, fishy for ammonia, and nail polish remover for ketones. Odor emissions peak during compost turning due to increased microbial activity, influenced by factors like time, handling methods, temperature, and humidity [5].

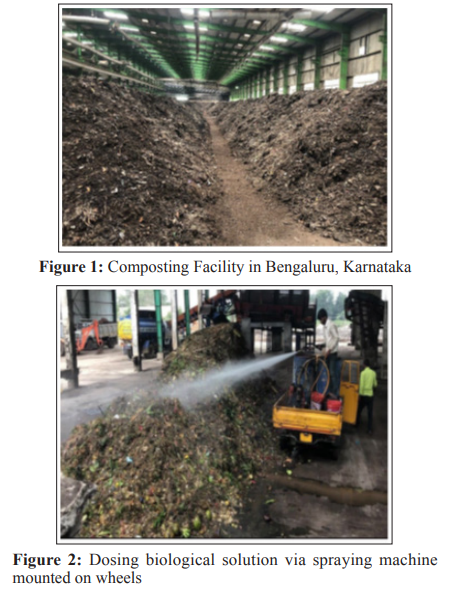

Bengaluru’s current capacity for managing municipal solid waste stands at approximately 2,100 TPD (Tons Per Day). The existing waste treatment facilities, including Mavallipura (600 TPD), Karnataka Composting Development Corporation Ltd. (KCDC - 300 TPD), and Terra Firma (1,500 TPD), fall short of achieving 100% waste processing. To address this, the government has sanctioned six new facilities at different locations, with capacities ranging from 200 to 500 TPD: Kannahalli, Seegihalli, Doddabidarakallu, Lingaderenahalli, Subrayanpalya, and Chikkanagamangala. Primarily designed for wet waste composting, these plants also incorporate screening for compost from mixed MSW and provisions for storing non-compostable/non-recyclable materials, aiming to enhance waste processing capabilities in the city [6]. This study centers on a Bengaluru-based composting facility, aiming to investigate the potential implementation of biological solutions to reduce odors generated in the composting process. This facility is dedicated to environmentally friendlyprocessing of urban and agricultural waste by creating compostbased organic manure and vermicompost. Each day, it handles around 90 tons of fresh municipal solid waste (MSW), and it can have an inventory of 25,000-30,000 tons of waste in different stages of being transformed into compost.

In this facility, a trial was conducted with 50 tons(T) of fresh municipal solid waste. To reduce interference from odors at the main site, a remote location was selected.

| Day | Dose of selected biological product |

Dosing methodology for biological solution |

| Trial 1: On 20 tons of fresh waste at a remote location. | ||

| Day 1 | 100 g | 10 T of fresh waste was unloaded on site. 100 g of selected biological product was mixed with 30 L of water and the active biological solution was sprayed on this 10 T waste pile. A bucket and a plastic cup were used for spraying active biological solution on the waste pile. |

| Day 2 | 100 g | 10 T of new waste was unloaded onsite. 100 g of selected biological product was mixed with 30 L of water and the active biological solution was sprayed on total 20 T of waste pile. |

| Day 3 | 100 g | Since significant reduction in odor was not observed on the first 2 days of trial, it was decided not to unload any more waste on site. Conclusion: Complete coverage could not be achieved using a bucket and cup. Change in dosing methodology: 100 g of selected biological product was mixed with 100 L of water and the active biological solution was sprayed on the existing 20 T of waste pile with the help of spraying machine mounted on wheels. |

| Day 4 | 100 g | 100 g of selected biological product was mixed with 100 L of water and the active biological solution was sprayed on the existing 20 T of waste pile with the help of spraying machine mounted on wheels (3-wheeler auto). |

| Day 5 | 100 g | 100 g of selected biological product was mixed with 100 L of water and the active biological solution was sprayed on the existing 20 T of waste pile with the help of spraying machine mounted on wheels (3-wheeler auto). |

| Trial 2: On 30 tons of fresh waste. The objective of this trial was to check, confirm, and conclude the duration required by selected biological product for reducing odor on the waste pile. j | ||

| Day 1 | 200 g | 30 T of fresh waste was unloaded on site. 200 g of select biological product was mixed with 100 L of water and the active biological solution was sprayed daily on 30 T of waste pile with the help of spraying machine mounted on wheels (3-wheeler auto). Note: the waste pile was turned on a daily basis and active biological solution was sprayed every time the waste pile was turned |

| Day 2 | 200 g | |

| Day 3 | 200 g | |

In Trial 1, there was no reported change in odor by field personnel on days 1, 2, and 3. However, on Day 4, implementing a proper spraying mechanism ensured complete coverage of the waste area, leading to a notable reduction in odor. By the 5th day inspection, complete odor reduction was reported. Even during the turning of waste, minimal odor was generated, and when the biological solution was sprayed after turning, it promptly eliminated the remaining odor. In Trial 2, a substantial reduction in odor was observed on the second day of applying the biological solution to a 30-ton waste pile. The trial concluded on the third day after confirmation from plant personnel that the odor had significantly decreased and was well under control.

The trial conducted at this composting site in Bengaluru proved highly successful. Biological solution implemented for this study comprised of bacillus and lactobacillus species was able to significantly reduce odor. This trial also highlighted the importance of correct application methodology and the significance of complete coverage while spraying the active biological solution. Applying air spray or surface treatment products containing masking agents, counteractants, neutralizers, and surfactant enhanced absorption agents is a possible approach for odor control. However, there is limited knowledge about their true efficiency and mechanism of action [7]. Tracking and managing odors pose inherent challenges, especially considering the subjective nature of human perception. Therefore, future trials should integrate the systematic generation of data on compounds responsible for odor during the composting process. This approach will provide a more comprehensive and objective understanding, ensuring a more accurate assessment of odor dynamics and facilitating targeted improvements in composting practices.