Author(s): Vrushank Mistry

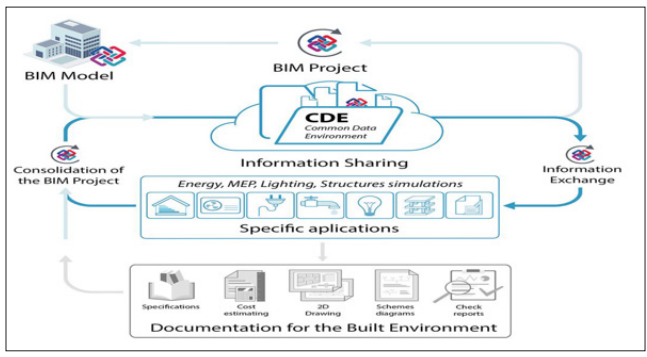

Figure 1: Building Information Modeling

In the contemporary landscape of architecture, engineering, and construction (AEC), Building Information Modeling (BIM) has established itself as a transformative force, revolutionizing traditional approaches to project planning and execution. As a sophisticated and comprehensive tool, BIM transcends mere digital representation, serving as an intricate nexus where design, data, and collaboration converge. Its capacity to create a virtual counterpart of building projects has not only elevated the efficiency of construction processes but has also fostered unprecedented levels of interdisciplinary collaboration among stakeholders.

This paper embarks on a focused exploration of the symbiotic relationship between BIM and Heating, Ventilation, and Air Conditioning (HVAC) automation, recognizing the potential for paradigm shifts in building design, construction, and operational management. BIM, with its ability to provide a centralized and interconnected repository of project data, offers a robust platform for stakeholders to visualize, analyze, and collaborate throughout the entire lifecycle of a building. Concurrently, HVAC automation aims to optimize the indoor environment, ensuring energy efficiency, occupant comfort, and operational resilience.

The convergence of BIM and HVAC automation introduces a novel dimension to the discourse on intelligent building systems. This research endeavors to unveil the profound synergies embedded in this integration, where the digital intelligence inherent in BIM models aligns seamlessly with the dynamic controls and optimization strategies of HVAC automation. By emphasizing these potential synergies, the paper seeks to navigate beyond the conventional silos of design and construction, envisaging a more holistic and interconnected approach to the built environment.

The investigation encompasses a multi-faceted analysis, ranging from how BIM facilitates precision in HVAC system design and layout during the planning phase to the real-time collaboration possibilities that bridge the gap between design intent and operational performance. The exploration further delves into the potential benefits of leveraging BIM in the operational phase, such as predictive maintenance, energy monitoring, and data-driven decision-making in HVAC automation.

In essence, this paper serves as a critical exploration of the convergence of BIM and HVAC automation, aiming to uncover not only the technical intricacies of their integration but also the transformative potential it holds for the AEC industry. By shedding light on these synergies, the research contributes to the discourse surrounding intelligent buildings, offering insights that resonate with professionals, researchers, and stakeholders engaged in the dynamic and evolving realm of modern construction and building management practices.

Building Information Modeling (BIM) is a comprehensive and collaborative approach to the design, construction, and management of buildings and infrastructure. At its core, BIM involves creating and managing a digital representation of the physical and functional characteristics of a facility. This digital model serves as a shared knowledge resource for information about a building, providing a platform for stakeholders to collaborate and make informed decisions throughout the entire lifecycle of a structure.

BIM involves the creation of a centralized and coherent digital model that encompasses both geometric and non-geometric information related to a building project. This model becomes a common reference point for all stakeholders.

BIM promotes collaboration and coordination among various disciplines involved in a construction project, including architects, engineers, contractors, and facility managers. The shared model allows real-time collaboration and reduces errors arising from miscommunication.

BIM integrates diverse data types and formats, ranging from 3D geometric models to specifications, schedules, cost estimates, and performance data. This integration enables a holistic understanding of the building's characteristics.

BIM supports the entire lifecycle of a building, from conceptualization and design through construction and operation to renovation or demolition. This lifecycle approach ensures continuity of information and facilitates effective facility management.

BIM enhances communication and collaboration among project stakeholders by providing a unified platform for sharing information. This leads to better decision-making and reduces the risk of misinterpretation.

BIM streamlines the design and construction processes by enabling real-time visualization, clash detection, and scenario analysis. This efficiency contributes to faster project delivery and cost savings.

The collaborative nature of BIM reduces errors and inconsistencies in project documentation. This, in turn, minimizes the need for rework during construction, saving both time and resources.

BIM facilitates effective facility management by providing a detailed digital representation of the building. This aids in maintenance planning, asset tracking, and performance monitoring throughout the building's operational life

BIM allows for the creation of detailed 3D models of HVAC systems, including ductwork, piping, and equipment. This precision aids in optimizing the layout for efficiency and ensures accurate spatial coordination with other building components.

BIM enables clash detection between HVAC components and other building systems early in the design phase. This proactive approach helps identify and resolve conflicts before construction, minimizing disruptions and rework.

BIM supports energy analysis for HVAC systems, allowing designers to simulate and optimize energy performance. This capability assists in making informed decisions to enhance energy efficiency and sustainability.

BIM generates accurate and up-to-date documentation for HVAC systems, including specifications, schedules, and maintenance requirements. This comprehensive documentation aids in construction planning and ensures that the installed systems align with design intent.

Building Information Modeling (BIM) integration with Heating, Ventilation, and Air Conditioning (HVAC) automation marks a transformative alliance that leverages digital intelligence to enhance the design, installation, and operational phases of HVAC systems. This section provides an overview of the seamless integration between BIM and HVAC automation, elucidating the ways in which these technologies collaborate to optimize building performance.

The integration involves embedding BIM-generated data and insights into the HVAC automation process, fostering a continuous flow of information from the design and construction phases to the operational life of the building. By bridging the gap between the static digital representation of BIM and the dynamic controls of HVAC automation, this integration unlocks unprecedented opportunities for precision, efficiency, and adaptability in building management.

The iconic Shard in London utilized BIM integration with HVAC automation for precise system design and clash detection. The integration ensured optimal performance of the HVAC systems in this complex architectural structure.

The National University Hospital in Singapore employed BIM integration with HVAC automation to enhance coordination during construction. The real-time collaboration facilitated efficient installation and minimized disruptions.

Denver International Airport utilized BIM integration with HVAC automation for energy performance analysis. The integration contributed to the airport's commitment to sustainability and operational efficiency.

These case studies exemplify successful implementations where the integration of BIM with HVAC automation has yielded tangible benefits in terms of design optimization, collaboration, clash detection, energy efficiency, and operational performance. They stand as testaments to the transformative impact of this integration in diverse real-world scenarios

BIM Tools and Software for HVAC System Design Building Information Modeling (BIM) has catalyzed a paradigm shift in HVAC system design, offering advanced tools and software that facilitate precise modeling, coordination, and This section provides an overview of the BIM tools and software specifically tailored for HVAC system design:

Autodesk's Revit MEP is a widely used BIM software that provides specialized tools for HVAC system design. It enables the creation of detailed 3D models of HVAC components, including ducts, pipes, and equipment. The software supports accurate spatial coordination and clash detection, enhancing collaboration among different disciplines involved in the project.

AutoCAD MEP is an extension of AutoCAD designed for mechanical, electrical, and plumbing (MEP) professionals. It includes features specifically geared towards HVAC system design, such as parametric components and specialized tools for creating and editing HVAC systems in 3D.

Carrier HAP is a BIM-compatible software used for accurate load calculations in HVAC system design. It allows designers to model building systems and analyze their performance, considering factors such as occupancy, lighting, and climate. The software seamlessly integrates with BIM platforms to enhance data exchange and collaboration.

MagiCAD is a BIM solution that integrates with Revit, offering specialized tools for HVAC system design. It includes a comprehensive library of manufacturer-specific product models, facilitating accurate equipment selection and placement within the BIM environment

BIM-enabled HVAC design allows for accurate load calculations by considering factors such as building geometry, occupancy, lighting, and climate. BIM tools, including Revit MEP and Carrier HAP, streamline the process of inputting data and performing complex calculations, ensuring precision in determining heating and cooling loads.

BIM platforms integrate with manufacturer databases, enabling designers to select HVAC equipment based on real- world product specifications. This ensures that the chosen equipment aligns with the project's requirements and allows for the seamless placement of selected components within the BIM model.

Parametric modeling in BIM tools facilitates the creation of intelligent HVAC components that can adapt to design changes. This dynamic modeling capability enhances the flexibility of equipment selection, enabling designers to explore various scenarios and optimize the system for performance and efficiency.

BIM-integrated tools support energy simulation for HVAC systems. By leveraging the 3D model and detailed component information, designers can simulate the performance of HVAC systems under different operating conditions. This enables the assessment of energy efficiency and informs decision-making for sustainable design.

BIM software allows for the simulation and analysis of airflow within HVAC systems. This capability ensures that the design meets performance requirements and helps identify potential issues, such as uneven air distribution or pressure imbalances, before construction.

BIM facilitates collaborative analysis by providing a shared platform where various stakeholders can contribute to system simulations. This collaborative approach ensures that the analysis considers input from multiple disciplines, resulting in a more holistic understanding of HVAC system performance.

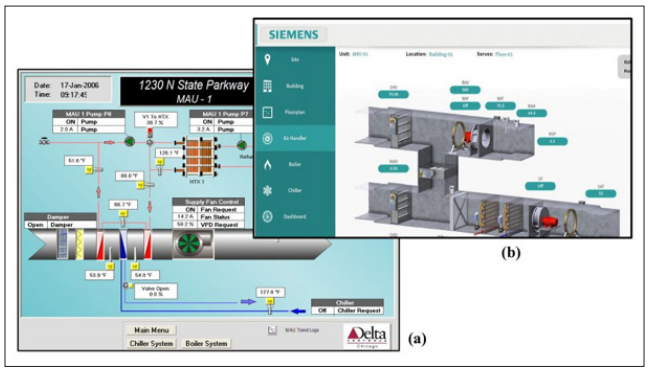

The integration of Building Information Modeling (BIM) with Heating, Ventilation, and Air Conditioning (HVAC) systems extends beyond the design and construction phases to offer valuable insights for real-time monitoring and control during the operational lifecycle. This section explores how BIM facilitates the integration of HVAC systems with smart building technologies:

BIM can integrate with IoT sensors and Building Automation Systems (BAS) to provide real-time data on HVAC system performance. This includes information on temperature, humidity, air quality, and equipment status. The 3D BIM model serves as a digital twin, enhancing situational awareness.

BIM-enabled HVAC systems allow for remote monitoring of building conditions. Facility managers can access the digital model to visualize the current status of HVAC components and make informed decisions for optimal operation. This remote accessibility enhances responsiveness and minimizes downtime.

BIM integration enables the implementation of dynamic control strategies based on real-time data. HVAC systems can adapt to changing conditions, adjusting parameters such as airflow, temperature, and ventilation in response to occupancy patterns, weather fluctuations, or other environmental factors.

BIM-integrated HVAC systems leverage real-time data to monitor the condition of equipment and components. Predictive maintenance algorithms analyze this data to identify potential issues before they escalate, allowing for proactive maintenance interventions and minimizing unplanned downtime.

BIM platforms can incorporate energy performance analytics tools that assess the operational efficiency of HVAC systems. By comparing actual performance against design specifications, facility managers can identify areas for improvement, optimize energy consumption, and implement targeted efficiency measures.

BIM supports simulation tools that model different operational scenarios for HVAC systems. Facility managers can use these simulations to optimize energy consumption, test the impact of system modifications, and develop strategies for energy- efficient operation.

BIM provides a centralized repository of information related to HVAC assets, including equipment specifications, maintenance history, and warranty details. This comprehensive asset information streamlines facility management, ensuring that maintenance activities are well-informed and executed efficiently.

BIM facilitates lifecycle cost analysis by considering the entire lifespan of HVAC assets. Facility managers can make informed decisions regarding repair, replacement, or upgrades based on a thorough understanding of the long-term costs associated with each asset.

Facility managers can utilize BIM for space and occupancy planning in conjunction with HVAC systems. This integration supports efficient space utilization, ensures proper ventilation, and facilitates modifications or expansions based on changing operational needs.

BIM-generated documentation aids in compliance management, providing facility managers with accurate and up-to-date information for regulatory requirements. This ensures that HVAC systems adhere to industry standards and local regulations throughout their lifecycle [1-12].

Figure 2: Building Information Modeling as An Effective Process for The Sustainable Re-Shaping of The Built Environment

Figure 3: Smart Building Automation

Figure 4: Management & Analytical Tools: a) Delta Orcaview Display of Air Handling Unit (AHU) https://www.deltacontrols.combSiemensApogeeInterfaceforTheSameAHUhttp://w3.usa.siemens.com/buildingtechnologies