Comparative Analysis of Concrete Water-Proofing Materials

Author(s): Reuben Peters Omale* and Aanu Aderonke Oguntade

Abstract

Concrete is porous when exposed to water, because water passes through its pores defacing the concrete and corroding the reinforcements, this overall effect weakens concrete. Waterproofing of concrete is very essential in building parts which are constantly exposed to moisture from ground water and rain water. This study compared bituminous felt with cementitious crystalline waterproofing materials for concrete. In this study, a particular square area of concrete slab was assumed, and a market survey was conducted to determine the cost of purchase and installation of bituminous felt and cementitious crystalline waterproofing materials for the assumed square area. The bill of quantities for both options was done to aid the comparisons and cost of maintenance of both materials. The results of the study showed that bituminous felt was the most widely used waterproofing material, while cementitious crystalline waterproofing material on the other hand is not a very popular material as most building professionals did not know about its existence. The market survey showed that it was cheaper to install cementitious crystalline waterproofing material than to install bituminous felt and the cost of maintenance of cementitious waterproofing material was also negligible compared to bituminous felt. Though cementitious crystalline waterproofing material is new in Akure market, it has a promising future in the construction industry not only in Akure but in Nigeria’s construction industry at large.

Introduction

Waterproofing is a process designed to prevent water from

penetrating a structure. It is typically done in various layers and

stages to create multiple barriers and prevent water from penetrating

the structure. A combination of such stages is referred to as creating

a ?Building Envelope?. Waterproofing becomes expedient in wet

environments or under water to specified depths. Waterproofing

protects the structural contents of a building from water infiltration

that can cause structural damage to the concrete or corrosion to the

imbedded steel. Every element of a building from the walls, roofs,

floors and so on should be water resistant or waterproof.

In construction, buildings are waterproofed using so many types

of waterproofing membranes, coatings and built-in systems. The

different waterproofing materials available today are: asphalt-andfelt built up system, bituminous membranes, polyurethane liquid

membrane, acrylic sealers, epoxy sealers, penetrating Sealers,

polyaspartic, and cementitious waterproofing, etc. Concrete is

porous, and if not waterproofed, can absorb water, waterborne

contaminants and chemicals that can cause deterioration. To protect

concrete and ensure it has a long serviceable life, waterproofing is

essential. Ensuring that water seepage in concrete can be prevented

and hydrostatic pressure resisted, as concrete can be waterproofed

from the positive (exterior) side, negative (interior) side or from

within the concrete itself (integral systems). Bituminous felt has

been used as a waterproofing system designed to protect residential

and commercial buildings. It is usually black in nature and is

often used to protect concrete surfaces from water infiltration.

One limitation of its use has been the black and grey colours, as

this has limited its use to places that would not be visible to the

general public.

Concrete is one of the prominent building materials used in Nigeria

today, it has been found to be of good compressive strength and

with the use of reinforcement of good tensile strength. Concrete

however is susceptible to cracks, shrinkage and when exposed to

moisture there is moisture expansion which weakens the concrete

and reduces the lifespan. To prolong the lifespan of concrete, it

therefore has to be waterproofed. There are various methods of

waterproofing concrete, ranging from bituminous felt, Penetrating

sealers, epoxy sealer, bentonite, to cementitious crystalline

waterproofing material. However, only two were focused on in this

research, these are: bituminous felt and cementitious crystalline

waterproofing material. These two materials were extensively

discussed in terms of what the materials are, the cost implication

of installation and maintenance.

This research is an in-depth study of bituminous felt and

cementitious crystalline waterproof coating for concrete. The

paper presents information on what exactly these materials are

in terms of their physical components, their uses and mode of

application. It also presents, detailed cost analysis (i.e. cost of

obtaining the materials, cost of installing the materials and cost of

maintaining the materials after installation), as well as the lifespan

of the two materials, which serves as the basis for drawing logical

conclusions on the comparative advantages and disadvantages of

both materials.

Problem Statement

Concrete waterproofing systems have been known to fail over the

years in Nigeria especially those used in concrete roofing. Quite

a number of concrete roofs begin to leak a couple of years after

construction, some are eventually converted to pitched roofs that

are covered with aluminium sheets. Although leakages may be as a

result of poor finishing of the waterproofing materials, it could also

be as a result of too shallow gradient especially in roofs that don?t

encourage run off. This paper looks at cementitious crystalline

waterproof coating and bituminous felt (which are modern

waterproofing materials) as a solution to concrete waterproofing

failure in Nigerian buildings.

Aim and Objectives

The aim of this study is to compare bituminous felt and

cementitious crystalline waterproofing materials for concrete,

which are both concrete waterproofing materials, with a view

towards recommending which amongst the two waterproofing

materials is more efficient.

The objectives of the study are to:

• Determine what exactly bituminous felt and cementitious

crystalline waterproofing materials are in terms of their

history, chemical and physical components, their uses and

mode of application.

• Carry out a detailed cost analysis of obtaining both materials

and installing them

• Evaluate the cost of maintenance after installation.

• Recommend the better option in-terms of cost, usage and

maintenance.

Literature Review

Introduction

Concrete is a mixture of cement, aggregates and water in controlled

proportions,[1] . The relative amount of each material (i.e. cement,

water and aggregates) affects the properties of concrete. Aggregates

should be strong and hard, to produce strong concrete outcome.

Aggregates should be clean, durable and chemically inactive so

that aggregates do not react with the concrete. Aggregates should

be stored where they will remain clean, separated from other

materials and dry. If the aggregates are wet, less water should be

used in the mix [2].

Cement reacts with water in a chemical process called hydration.

Many additional ingredients can be added to the basic concrete

mix in order to change the properties of the resulting concrete.

Some common admixtures are accelerators which speed up

the hydration process (often used in colder environments) and

retarders which slow down the hydration process (often used in

hotter environments). Plasticizers improve the workability of

wet concrete while pigments change the colour of concrete for

aesthetic reasons [3].

Properties of Concrete

Concrete has three different states: the plastic state, setting state

and the hardened state [2]. Concrete has the following properties:

• Workability

Workability means how easy it is for concrete to be placed,

handled, compacted and finished. To improve the workability

of concrete some more, cement paste should be added, well

graded aggregates should be used, and plasticizers could also

be added [2] (Cement Concrete and Aggregates Australia,

2010).

• Cohesiveness

This is how well concrete holds together when in a plastic

state.

• Strength

Concrete has strong compressive strength and poor tensile

strength. This is why concrete is usually reinforced using

steel or various fibers. Denser concrete is stronger and more

watertight (or less permeable), than less dense concrete.

• Durability

The stronger the concrete the more durable it is.

Limitations of Concrete

• Concrete has low tensile strength thus the need for

reinforcement.

• Concrete has low ductility.

• Concrete is susceptible to cracking due to drying, shrinkage

and moisture expansion.

• If soluble salt is present in concrete, it may lead to

effervescence when it comes in contact with water, this has

adverse effects on reinforcements, that is if the concrete is

reinforced.

• Concrete has low permeability when exposed to water; water

passes through its pores through capillary action. If concrete

is constantly exposed to this kind of condition, it becomes

weak and infested with lichen, moss and may disintegrate or

break, thus the need for waterproofing.

Concrete is used in several stages and aspect of construction.

Concrete is commonly used in the substructures for foundation

footing, and flooring. In the super structure, it is used for columns,

beams, suspended floors, decking and so on. One of the critical

limitations of concrete is that it is porous (i.e. allows water to pass

through) and when used as a decking for buildings, this limitation

is a very serious issue. It is this limitation that creates the need

to waterproof concrete.

Waterproofing of Concrete Roofs

Waterproofing, a process designed to prevent water from

penetrating a structure, is typically done in various layers and

stages to create multiple barriers and prevent water from seeping

into the structure. A combination of such stages is referred to

as creating a ?Building Envelope?. Often times, not enough

importance is given to this crucial aspect of construction because

there is low awareness on modern waterproofing techniques and

little expertise on some of the modern techniques of waterproofing.

Stages of Concrete Roof Waterproofing

There are basically two stages in waterproofing of concrete roofs;

there is the construction stage and post construction stage.

Construction Stage

The construction stage involves the use of the right construction

techniques and the right waterproofing method. During the

construction stage concrete should be mixed to the right watercement ratio. It should also be properly compacted as water would

flow through any pore in the concrete through capillary action.

The concrete should be allowed to cure properly; plumbing fittings

embedded in the concrete should be properly done to prevent

leakages from pipes. It is very important that concrete roofs have

the right slope (gradient). There should be no undulation in terms

of construction since this allows for free flow of water [4].

The waterproofing method to be used should have been determined

and care should be taken to apply waterproofing materials

according to the manufacturer?s instructions, as this is one of the

reasons for failure in waterproofing systems.

Post Construction Stage

Waterproofing should not only be done during construction, but

also after construction, as existing building might experience

dampness [4]. It appears better to waterproof concrete in roofs

especially when the building project is close to the end of

construction stage, before handing over is done, to prolong the

life of the water-proofing material (WPM) and encourage its

lifespan to be as long as the building. This can also be in form of

maintenance as some waterproofing materials have different life

span or effective life after which they begin to fail.

Methods of Concrete Waterproofing

Concrete roofing is the most crucial segment of a building, and

it is exposed to direct climatic variations, extremes of rainfall

and structural movements caused within the building. So every

effort should be made at the design stage to ensure that a proper

protection system has been incorporated. It has often been found

that the economic solution is not always the best solution. So, the

system, which assures maximum protection, should be selected

even though it may cost little more [4]. A building or structure

needs waterproofing as concrete is porous and will not be watertight

on its own. Flat roofs in modern times are generally constructed

of reinforced concrete. This material removes all the problems

of flat roofs except that the roof should be made water proof by

employing any of the various methods available for waterproofing.

The various methods available for waterproofing are: Cementitious

Waterproofing, Liquid Waterproofing Membrane, Bituminous

Coating Waterproofing, Bituminous Membrane Waterproofing,

Polyurethane Liquid Membrane Waterproofing etc. However,

only two materials will be considered here for comparison and

these are cementitious crystalline waterproofing material and

bituminous felt waterproofing material.

Bituminous Felt Waterproofing Materials

Bituminous felt is a waterproofing material which uses tar.

Bituminous waterproofing materials are made from bitumen which

is a black sticky mixture of hydrocarbons used for waterproofing

basements and flat roofs, and for damp-proof courses. It is

obtained from natural deposits (asphalt) and from the distillation

of petroleum [5]. The physical properties of bitumen make it

an attractive option in waterproofing application. Today, there

are various bituminous waterproofing products in the markets,

some of the bituminous waterproofing products available are:

Polyurethane, Cementitious Coating, EPDM Rubber, Rubberized

Asphalt, Thermoplastic, Bituminous Membrane, and PVC

Waterproofing Membrane amongst others.

Polymer Modified Bitumen Membranes

Polymer modified bitumen membranes are made by mixing

thermoplastic polymers with straight-run or oxidized bitumen

and a mineral filler, and then coating a fiberglass or polyester mat

or other reinforcements with the mixture. The polymer modifier

used may be atactic polypropylene (APP) or styrenebutadienestyrene (SBS) block copolymer, or other polymers with the same

chemical families [6].

The main difference between Atactic polypropylene (APP) and

styrenebutadiene-styrene (SBS) is that APP is a plastic asphalt i.e.

it is modified with plastic, while SBS is an elastic asphalt i.e. it is

modified with synthetic rubber [7]. When torching APP it melts

like candle in its molten state. SBS on the other hand behaves

differently when warm, it is very sticky. When SBS goes through

elongation it fully recovers when it is released.

Polymer modified bitumen membranes can be heat (torch) applied,

with hot asphalt or with adhesive. The torch application technique

requires less man power, and is applied by applying heat evenly

to the back side of the membrane using a torch (See plates 1 and

2). In hot application the hot bitumen can be mopped or poured

into place, or applied with a mechanical spreader or felt-laying

machine [6]. The adhesive application can be done by applying

adhesive on the concrete surface before rolling out the membrane

on it, it requires more finesse.

Plate 1: Heat (torch) application of polymer modified bitumen

membranes.

Source: Construction Update, (2012)

Plate 2: Hot application of polymer modified bitumen membranes.

Source: Davidhazen.com, (2017)

Cementitious Waterproofing

Cementitious waterproofing is the easiest method of waterproofing

in construction. The materials for cementitious waterproofing

are easily available from suppliers of masonry products, and

they are easy to mix and apply. It could be applied using a long

handle brush which makes the work easier or it could be mixed

with concrete [8]. A picture showing the application process can

be seen in plate 3.

There are basically two forms of cementitious water proofing, both

of which are non-decorative. The first consists of Portland cement,

fine aggregate, and sometimes acrylic or other plastic admix. The

second form of cementitious waterproofing is hydraulic cement,

which is a compound of cement with rapid setting non-shrinking

hydraulic materials. Hydraulic cements are used for many purposes

which include sealing holes, cracks, and open joints.

The principal disadvantage is that cementitious products do not

contract or expand to any degree worth mentioning, though they

will prevent water penetration but will not tolerate joint or crack

movement [9]. Therefore, cracks or joints in buildings need to

be treated specially.

Cementitious Crystalline Waterproofing Material for Concrete

Cementitious crystalline waterproofing material for concrete

was invented decades ago; it makes up for the shortcomings

of traditional waterproofing materials. Cementitious capillary

crystalline waterproofing coating is a kind of powdery material

substrate on cement and quartz sand, incorporated into a variety

of active chemical substances [10].

Crystalline technology is the major class of integral waterproofing.

They react with calcium hydroxide and other products of cement

hydration and form non soluble crystals that plug and fill the pores

and micro cracks in the presence of water [11]. It works from both

the positive exteriors and negative interiors and even after years.

It seals cracks automatically that are not more than 4mm wide. It

can form stable crystal by polymerization to prevent water, so it

may play a role in remedying a defect automatically [10].

Plate 3: Application of Cementitious Waterproofing Material

Source: Arcon supplies, (2017).

Comparative Study of Conventional and Modern

Waterproofing Techniques

Water seepage can cause damage to buildings and thus, the

need for waterproofing and selecting the right waterproofing

materials [11]. Saurabh and Ghadge, (2016) reported of a study

that involved traditional (tarfelt, Brick bat coba) and modern

(coatings, integral) approaches to waterproofing, in a comparative

study involving both materials. The cost, durability and ease of

use of the various waterproofing methods were the criteria used

in drawing conclusions in the study.

Findings from the study revealed that traditional waterproofing

methods were relatively less expensive to install, easy to use

but were not long lasting and as a result not economical in the

long run. Modern waterproofing methods on the other hand, are

quite expensive compared to traditional methods, and are easier

to install. They also had a more lasting effect and, in the case of

integral waterproofing, they last the entire life time of the concrete,

thus, making modern waterproofing materials more economical

in the long run [11].

Research Methodology

Approach and Design

Mixed method approach was used for this study, and this involved

the use of quantitative and qualitative approaches. Quantitative

approach involves the generation of data in quantitative form

which can be subjected to extensive quantitative analysis in a

formal and rigid fashion, while qualitative approach on the other

hand is concerned with subjective assessment of attitudes, opinions

and behaviours [12]. A descriptive survey design was also adopted.

Descriptive research includes surveys and fact-finding enquiries

of different kinds, the major purpose of descriptive research is

the description of the state of affairs as it exists at present [12]. In

this study, information was got through personal interviews and

questionnaires, which were physically administered by the authors.

The study was carried out within the confines of Akure metropolis,

and the Arakale market in Akure was visited for existing and

current market prices of waterproofing materials. There, two

sample products were selected, comprising bituminous felt and

cementitious crystalline waterproof coating for concrete. The

cost of the two samples was also determined from the various

tradesmen of the products. The costs of installing the materials

were also obtained from various artisans on the field and an

average of cost implication was arrived at by a quantity surveyor

by using bill of quantities (BOQ).

Besides the visit to Arakale market, data collection was also sought

out from the information concerning the cost of installation of these

materials as obtained from quantity surveyors and contractors.

Data Collection

Both primary and secondary data were used in this research.

Primary data were obtained by conducting interviews and

administering questionnaires as well as market surveys. The

interview method of collecting data involved presentation of

oral-verbal stimuli questions and replies in form of oral-verbal

responses, while a questionnaire containing a set of questions

was arranged in a definite order to elicit information from

respondents [12]. However, secondary data were sourced from

online brochures, published and unpublished articles written on

bituminous felt and cementitious crystalline waterproof materials

for concrete.

The interview questions were arranged in such a manner that

structured questions were for the quantitative data and unstructured

for the qualitative data. The questions were designed to obtain

information on the experiences of various building professionals

in the use of the materials under study.

Data Analysis

The data obtained were recorded, coded and tabulated. Bills of

quantities were prepared for both materials using the current

market prices and labour cost of materials. The data were tabulated

because it facilitated the process of comparison and provided

the basis for the various statistical computations used. A bar

chat (figure 1) was also used to show comparisons between the

two materials. After data was collected and collated, they were

analysed using SPSS version 20.

Results

Calculations for the Cost of Purchasing Cementitious

Crystalline Waterproofing

Materials (CCWPM) for Concrete.

The calculations were done for two options for the application

of cementitious crystalline waterproofing materials for concrete.

The first option was for the application of cementitious crystalline

waterproofing material for concrete to be used in the casting of a

150mm thick concrete slab. For the casting option, the concrete

mix ratio was assumed to be 1:2:4. While the second option

was for the application of cementitious crystalline waterproofing

material for cement to be used in the plastering of a 12.5 mm thickmix. For the last option, it was assumed that the mix ratio for the

mortar was 1:4. These two options were arrived at and adopted

for this study since concrete slabs thickness is usually 150mm and

plaster?s thickness is usually 12.5mm. Therefore, 12.5 mm was

considered and adopted as the thickness of cement plaster over

concrete slabs or horizontal walls that involve the use of CCWPM.

The area of the concrete slab that was used throughout the study

for the calculations was uniform, although it was arbitrarily chosen

as 5.1 x 6.45 m2

.

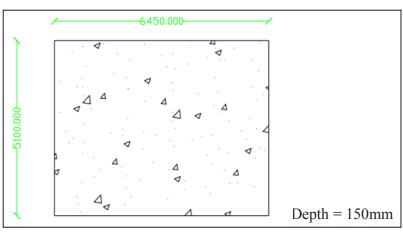

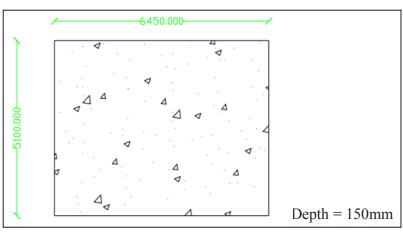

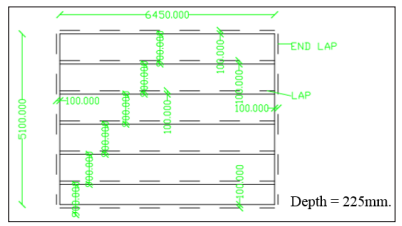

Figure 2: showing dimension of concrete slab in millimetre (mm).

Source: Author?s archive, 2019.

Option 1 (For 150 mm Thick Concrete Slab)

Volume of concrete = 5.100m x 6.450m x 0.150m = 4.934m3.

Mix ratio: 1:2:4.

Therefore: 1 + 2 + 4= 7.

Therefore: 1/7 x 4.934m3

= 0.705m3

.

Therefore: 4.934m3 / 0.705m3 = 6.99 cement bags of 50kg, which

is approximately 7 no. of 50kg bags of cement.

One bag of 500g of cementitious crystalline waterproofing material

=⩵750.

Principle of application is 500g of cementitious crystalline

waterproofing material to 1 50kg cement bag according to the

manufacturer of the product gotten from the market.

Therefore: 7 bags of 500g of cementitious crystalline waterproofing

material for 7 cement bags of 50kg = ⩵750 x 7 = ⩵5,250.

Also cost of 1 bag of cement is ⩵ 2,500. Therefore, 7 x ⩵ 2,500

= ⩵17,500

Cost of 7 bags of CCWPM + 7 bags of cement = ⩵5,250 + ⩵17,500

= ⩵ 22,750

Therefore, cost per m3 = ⩵22,750/4.934m3

= ⩵ 4,611.00

Option 2 (For Plastering 150 mm Thick Concrete Slab With

a Screed Of 12.5mm Thick)

Volume of mortar needed for the top and bottom sides = 5.1m x

6.45m x 0.125m x 2 = 8.22m3

Volume of mortar needed for both sides = 5.1m x (0.15+0.125+0.125)

m x 0.125m x 2 = 0.228m3

.

Total volume of mortar needed = 8.22m3

+ 0.228m3

= 8.45m3

.

Mix ratio: 1:4.

Therefore: 1 + 4= 5.

Therefore: 1/5 x 8.45m3

= 1.69m3

, which is approximately 2 cement

bags of 50kg,

One bag of 500g of cementitious crystalline waterproofing material

= ⩵750

Principle of application is 500g of cementitious crystalline

waterproofing material to 1no of 50kg cement bag according to

the manufacturer to the product gotten in from the market.

Therefore: 2no of 500g of cementitious crystalline = ⩵750 x 2

= ⩵1,500.

And 2 no bags of 50kg cement bags = 2 x ⩵ 2,500 = ⩵ 5,000

Therefore, total cost for cement bags and cementitious crystalline

= ⩵ 5,000 + ⩵1,500 = ⩵7,500

Therefore, cost per m3 = ⩵7,500/8.45m3 = ⩵888.00

Calculations for the Cost of Purchasing Bituminous Felt

The calculations done were based on the cost of 2mm and 3mm

thick bituminous felt respectively.

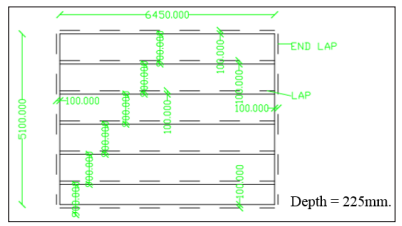

Figure 3: showing application of bituminous felt in millimetre

(mm).

Source: Author?s archive, 2019.

Minimum side lap = 100mm = 0.1m.

One run = 6.450m + 0.2m lap = 6.650.

Number of runs needed = 6.

1 yard of bituminous felt is 1m by 36 inches.

1inch = 2.54cm = 0.0254m.

Therefore: 6.650m/0.0254m = 261.811inches.

36inches = 1yard.

Therefore: 6.650m = 261.811inches/36inches = 7.272yards.

Number of yards needed for one run = 7.272yards which is

approximately 7.3yards needed.

Number of yards needed for 6 runs = 7.3 x 6 = 43.8 ≈ 44 yards.

Option 1 for 2mm Thick Bituminous Felt

Cost of 1yard of 2mm thick bituminous felt = ⩵800.

Therefore 44 yards of 2mm thick bituminous felt = ⩵800 x 44

= ⩵35,200.

Option 2 for 3mm Thick Bituminous Felt

Cost of 1yard of 3mm thick bituminous felt = ⩵1,000.

Therefore 44 yards of 3mm thick bituminous felt = ⩵1,000 x 44

= ⩵44,000.

Bill of Quantities (BOQ) for the Cost of Installing Cementitious

Crystalline Waterproofing Materials in Concrete

This section shows BOQ prepared for the two options for the

application of cementitious crystalline waterproofing materials

for concrete. In the tables below it was observed that the cost of

workmanship was nil, and this is due to the fact that the material

(which is in powder form) is added to dry cement then properly

mixed, before the slab is cast or plastered thus no cost of labour

is incurred.

Table 1: BOQ option 1 for cementitious crystalline waterproofing material for concrete

| Item |

Description |

Unit |

Qty |

Rate (⩵) |

Cost (⩵) |

| 1 |

Cost of cementitious crystalline

waterproofing material in concrete. |

m 3 |

0.705 |

32,269 |

22,749 |

| 2 |

Cost of workmanship. |

______ |

____ |

_________ |

_________ |

| Total |

|

|

|

|

≈ ⩵22,750 |

Table 2: Showing BOQ option 2 for cementitious crystalline waterproofing material for 12.5mm plaster

| Item |

Description |

Unit |

Qty |

Rate (⩵) |

Cost (⩵) |

| 1 |

Cost of cementitious crystalline

waterproofing material in concrete |

m 3 |

1.644 |

4,562 |

7,499 |

| 2 |

Cost of workmanship. |

______ |

____ |

_________ |

_________ |

| Total |

|

|

|

|

≈ ⩵7,500 |

Source: Author?s market survey, 2019.

In comparing tables 1 and 2, it can be deduced that it is more expensive to cast the same floor area of concrete (N22,750) by integrating

cementitious crystalline waterproofing material into the mix than to plaster or screed the same floor area using the same material at

(N7,500). This is because the quantity needed for CCWPM is more in concrete (7 bags of cement + 7bags of ccwpm) than in plastering

the same floor area (2 bags of cement + 2 bags of ccwpm), considering the thickness of both construction elements.

Bill of Quantities Showing the Cost of Installing Bituminous Felt

This section shows BOQs prepared for both 2mm and 3mm thick bituminous felt and their various cost implications by using gas

and felt adhesives. In the tables below it has been assumed that 20liters of bituminous felt adhesive will be sufficient for covering the

specified floor area of 5.1m2 x 6.45m2. The cost of labour, hot mopped asphalt and the bituminous felt were gotten from interviews

with three artisans who install bituminous felt and the average costs were used for these calculations. Tables 3 & 4: Show BOQ

options 1 & 2 for 2mm thick bituminous felt using adhesives and gas respectively, while tables 5 & 6 show BOQ options 1 and 2 for

3mm thick bituminous felt using adhesives and gas respectively.

Table 3: BOQ option 1 for 2mm thick bituminous felt.

| Item |

Description |

Unit |

Qty |

Rate (⩵) |

Cost (⩵) |

| 1 |

Cost of 2mm thick bituminous felt |

Yards |

44 |

800 |

35,200 |

| 2 |

Cost of bituminous felt adhesive |

Liters |

20 |

400 |

8,000 |

| 3 |

Cost of workmanship. |

m 2 |

32.895 |

650 |

22,000 |

| Total |

|

|

|

|

N65,200 |

Source: Author?s market survey, 2019.

Table 4: BOQ option 2 for 2mm thick bituminous felt

| Item |

Description |

Unit |

Qty |

Rate (⩵) |

Cost (⩵) |

| 1 |

Cost of 2mm thick bituminous felt |

Yards |

44 |

800 |

35,200 |

| 2 |

Cost of gas |

Kg |

2 |

500 |

1000 |

| 3 |

Cost of workmanship and lease of touch. |

m 2 |

32895 |

650 |

22000 |

| Total |

|

|

|

|

N58,200 |

Source: Author?s market survey, 2019.

In comparing tables 3 & 4, it can be deduced that it is cheaper to use gas than adhesives in installing 2mm thick bituminous felt over

a surface area of 5.1 x 6.45m2, while the N7,000 difference may appear small in amount, with larger surface areas, it will definitely

become costlier.

Table 5: BOQ option 1 for 3mm thick bituminous felt

| Item |

Description |

Unit |

Qty |

Rate (⩵) |

Cost (⩵) |

| 1 |

Cost of 2mm thick bituminous felt |

Yards |

44 |

1000 |

44000 |

| 2 |

Cost of bituminous felt adhesive |

Liters |

20 |

400 |

8000 |

| 3 |

Cost of workmanship. |

m 2 |

32895 |

650 |

22000 |

| Total |

|

|

|

|

⩵74,000 |

Source: Author?s market survey, 2019

Table 6: BOQ option 2 for 3mm thick bituminous felt

| Item |

Description |

Unit |

Qty |

Rate (⩵) |

Cost (⩵) |

| 1 |

Cost of 2mm thick bituminous felt |

Yards |

44 |

1000 |

44000 |

| 2 |

Cost of gas |

Kg |

2 |

500 |

1000 |

| 3 |

Cost of workmanship and lease of touch. |

m 2 |

32895 |

650 |

22000 |

| Total |

|

|

|

|

N67,000 |

Source: Author?s market survey, 2019.

In comparing tables 5 and 6, the same scenario plays out like in

tables 3 and 4, with a difference of N7,000 in using adhesives

or gas. This result shows that a difference of N7,000 is realized

between using adhesives or gas. However, since 3mm thick

bituminous felt is thicker in width than 2mm, it is advisable to use

3mm than 2mm, but there is a difference of N8,800 between using

3mm and 2mm with adhesives and gas, and this cost (N8,800)

will definitely increase as floor area increases.

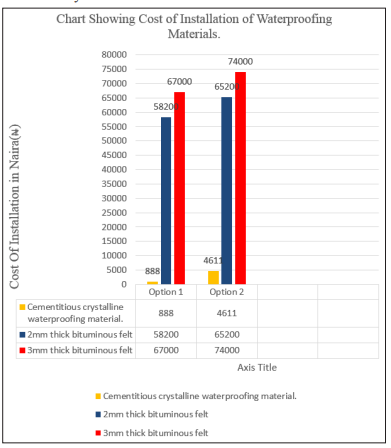

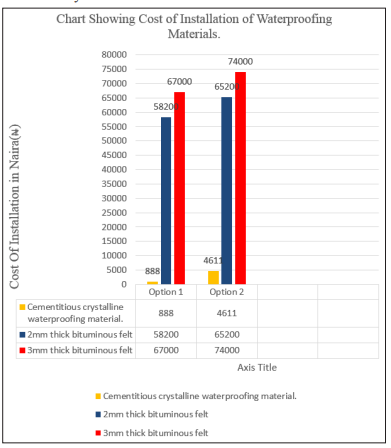

Figure 1: Bar chat comparing cost of installing bituminous felt and

cementitious crystalline waterproofing material. Source: Author?s

market survey, 2019.

The bar chart in Figure 1 clearly shows the difference in cost of

using cementitious crystalline waterproofing material, 2mm thick

bituminous felt and 3mm thick bituminous felt for the same floor

area of 5.1m2

x 6.45m2

= 32.89m2

. It can be clearly seen that

ccwpm is cheaper to use in concrete and in plaster compared to

2mm thick bituminous felt and 3mm bituminous felt that covers

the same surface area.

Summary of Results

From the cost analysis done which showed the cost of purchase

and cost of installation of cementitious crystalline waterproofing

material and bituminous felt, it was established that:

- The cost of purchase of bituminous felt is more than the

cost of purchase of cementitious crystalline waterproofing

material.Summary of Results

- There is no labor cost for the application of cementitious

crystalline waterproofing material as the material is added

to the cement during the casting or plastering of the concrete

slab.Summary of Results

- The cost of purchase and installation of 3mm thick bituminous

felt is more than the cost of purchase and installation of 2mm

thick bituminous felt.

- The cost of installation of 2mm and 3mm thick bituminous

felt is higher than the cost of installation of cementitious

crystalline waterproofing material.

- The cost of maintenance of bituminous felt is high compared to

the cost of maintaining cementitious crystalline waterproofing

material. This is due to the need to replace damaged portions

of the material during maintenance, also because bituminous

felt would need to be replaced after expiration of its durability

period. Cementitious crystalline waterproofing material on the

other hand can last throughout the life span of the concrete

even as there is no need for replacement.

Discussions

This study found out through calculations of existing market

prices that the cost per m3 of casting 150mm thick of r.c slab

using ccwpm is N 4,611 , while the cost of plastering the same

cubic meter using ccwpm is N 888. This tends to show that it is

more expensive to cast concrete slabs using ccwpm than plastering

the same cubic meter using ccwpm. With this knowledge, it will

encourage clients and contractors to make early decisions of

considering the use of ccwpm in the construction of concrete,

concrete slabs or using ccwpm in plastering. However, in buildings

where construction was completed without the use of dpm (damp

proof membrane) or ccwpm in casting concrete slabs and moisture

tends to adversely affect the superstructure of such buildings, it is

advisable to use ccwpm in plastering or re-plastering as the case

may be, since it was omitted at the initial stage during construction,

because it is cheaper to install, with no workmanship cost and no

maintenance cost throughout the lifespan of the building.

Findings from this study further reveal that 3mm thickness of

bituminous felt costs N44,000, while that of 2mm thickness costs

N35,200, (for the same floor area) indicating N9,800 difference

between both materials. While this difference may appear small,

when large surface areas are covered, the difference in cost may

become large. Also, while both materials are good and only

different marginally by 1mm thickness, if there are adequate and

sufficient funds available, it is advisable to opt for 3mm bituminous

felt for water proofing construction because of its thicker gauge.

However, where there is paucity of funds for a construction project,

the building professionals should opt for 2mm thick bituminous

felt material, but should be adequately and well finished using

adhesives or touch flame.

In the use of adhesives or touch flame the study found that it

is cheaper to use touch flame for sticking bituminous felt than

using adhesives for binding. It was discovered that whether 2mm

or 3mm is used on site, the difference in cost is N7000 betweenboth materials. The study found that it will cost N65,200 to

use adhesives for 2mm thick bituminous felt, while it will cost

N58,200 to use touch flame for 2mm thick bituminous felt on

the same surface area. It also found that it will cost N74,000 in

using adhesives for 3mm bituminous felt and N67,000 in using

touch flame for 3mm on the same surface area. While it appears

like using touch flame is cheaper (if it is properly done), than

using adhesives (if well done too), using adhesives for bonding

bituminous felt may detach in the continuous presence of water

seepage and high moisture. Therefore, building professionals

should take decisions early on which water proofing materials

should be used on construction projects on time, considering all

the factors stated above in this study. However, the study advises

further that in projects that were completed and plastered without

considering water proofing materials, the cost of hacking surfaces

or removing parts of previous plaster before re-plastering will

increase the cost of re-plastering with the new wpm in mind,

and re-plastering such surfaces is cheaper when ccwpm is used

compared to using ccwpm in concrete.

Recommendations and Conclusion

Recommendations

After a diligent study on bituminous felt and cementitious

crystalline waterproofing materials for concrete the following

recommendations were made to guide in the selection of a

waterproofing material for concrete:

Extensive research and study of the various waterproofing options

should be available before deciding on which waterproofing

materials to go for. (During the course of the study it was observed

that majority of the professionals who filled the questionnaires did

not know about cementitious crystalline waterproofing material.

They would therefore not recommend a material for use if they

are not aware that the material exists in the market. It would be of

great benefit if building professionals continually make adequate

research and findings about new construction materials, not only

in waterproofing techniques, because as technology advances,

newer and better solutions to waterproofing and construction

problems will emanate).

Proper study on the waterproofing material and the application

method that has been decided to be used must be done on time

before construction commences. There are various application

techniques, various temperature and environmental conditions

in which different waterproofing materials are to be applied. If

these conditions are not in place or attention is not paid to proper

application techniques, there is the probability of waterproofing

failure. So, professionals ought to be aware of the details involved

before they decide on which material to use.

- For future construction works on concrete, cementitious

crystalline waterproofing materials should be used instead

of bituminous felt as this is more cost effective in the

short run and also in the long run. Cementitious crystalline

waterproofing material also protects concrete from within

and has the ability to fill micro-pores of concrete.

- For existing concrete works which have not been waterproofed,

cementitious crystalline waterproofing material should be

used during the plastering, the plastering should however be of sufficient thickness of 12.5mm but not exceeding 15mm.

- For buildings in which bituminous felt has already been

used for waterproofing, in subsequent maintenance or after

the expiration of the existing bituminous felt, it should be

replaced with better updated versions of modified bituminous

felt material that are more durable than the non-modified

version. The affected area should be removed and re-plastered

with 12.5mm thick of cementitious crystalline that has been

thoroughly mixed with mortar for re-plastering.

Conclusion

This study was able to carry out in-depth research by comparing

two waterproofing materials for concrete, through market surveys,

comparing prices of procuring such materials through BOQs and

cost of maintenance of individual items, including interviews

with construction professionals. Findings from the study were

outstanding from the comparisons carried out on the two materials,

as it revealed that cementitious crystalline waterproofing material

has not been given widespread recognition, though it is more

cost effective compared to bituminous felt. The cost of purchase,

installation and maintenance of bituminous felt outweighs that of

cementitious crystalline waterproofing material. Cementitious

crystalline waterproofing material is not widely known and used by

construction professionals around this clime in Nigeria, but in the

future, it may become the most widely used waterproofing material

if the knowledge and awareness of the material is increased. Public

and private buildings, especially private residential buildings

that have been inhabited that omitted the use of DPC (damp

proof course) or DPM (damp proof membrane) due to moisture

seepage through concrete, can opt for cementitious crystalline

waterproofing material as a last resort, since it will be extremely

difficult to place DPC or DPM when construction is completed

and the buildings have been inhabited or put in use. Considering

the cost of construction with ccwpm and bituminous felt in a

building, it is obviously worth it, because of the inconveniences

and defacing aesthetics associated with dampness and water

seepage into concretes within buildings [ 13-15].

This study only observed analyses involving horizontally cast

reinforced concretes, horizontally plastered surfaces, and vertically

inclined plastered surfaces, but did not consider vertically cast

concrete (i.e reinforced columns) in its analyses and calculations.

Therefore, authors may consider other concrete castings like

the vertically inclined cast concrete etc. For further studies,

researchers may compare two or more other waterproofing

materials for concrete besides the ones that were studied here, and

make comparisons with this study in order to ascertain the most

effective, and the most economically viable of all the waterproofing

materials, so as to save money for optimum efficiency.

References

- Greeno R, Chudley R (2010) Building construction handbook

(8th ed.). London: Taylor and Francis.

- Australia, Cement Concrete, Aggregates (2010) Concrete

Basics: A Guide to Concrete Practice, (7th ed.) 7: 2-3, 7: 6-8.

- Construction Knowledge (2017) Concrete. Retrieved from

http://www.constructionknowledge.net/concrete/concrete_

basics.php

- Construction Updates (2012) Water proofing for

roofs. Retrieved from Construction Updates: https://

constructionduniya.blogspot.com/2012/02/water-proofingfor-roofs.html

- Henry J C, Peter R S (2004) Dictionary of architectural and

building technology (4th ed.). London: Spoon press.

- The Asphalt Roofing Manufacturers Association Report

(2011) The Bitumen Roofing Industry - A Global Perspective:

Production, Use, Properties, Specifications and Occupational

Exposure.

- Tradesmanroofing.com (2017) Tradesman, 2017. SBS

vs. APP- what?s the difference? Retrieved from www.

tradesmanroofing.com

- Theconstructor.org. (2017) Types of concrete waterproofing

materials. Retrieved from https://theconstructor.org/concrete/types-waterproofing-methods-construction/10856/

- Concrete Network (2017) Choosing Waterproofing Products.

Retrieved from www.concretenetwork.com/waterproofing

concrete foundations/cementitious waterproofing.html.

- Guo-Zhong L, Wei-Xuan Z, Li-Juan Z, Xiu-Jua (2014) The

Analysis on Mechanism and Application of Cementitious

Capillary Crystalline Waterproofing Coating. Proceedings

of the International Conference on Mechanics and Civil

Engineering (ICMCE 2014), held at Wuhan 156 - 161.

- Saurabh B G (2016) Comparative Study of Conventional and

Modern Waterproofing Techniques. International Journal of

Engineering Research, 5: 32-36.

- Kothari C (2004) Research methodology, methods and

techniques (2nd ed.). New Delhi: New Age International

(P) Ltd., Publishers.

- Construction Review (2015) Waterproofing concrete: why

waterproofing is a necessary exercise in construction. Retrieved

from Construction Review: https://constructionreviewonline.

com/2015/11/waterproofing-concrete/

- Fixit (2017). Dr. Fixit General waterproofing brochure.

Retrieved from Dr. Fixit.co: http://www.drfixit.co.in/library/

guides/brochure-4-0.html

- Washington State Department of Transportation in

Cooperation with United States Department of Transportation.

View PDF