Author(s): Anand Kumar Percherla

In the rapidly evolving landscape of business process optimization, the integration of Robotic Process Automation (RPA) with SAP systems has emerged as a transformative solution. This paper explores the synergy between UiPath RPA and SAP, shedding light on the potential for enhanced efficiency, accuracy, and scalability in enterprise processes. The abstract delves into the key concepts, challenges, and benefits associated with SAP logistics process automation using UiPath, offering insights for organizations seeking to streamline their operations through advanced automation.

As organizations strive to stay competitive in an increasingly digital world, the optimization of business processes becomes paramount. Enterprises worldwide rely heavily on SAP (Systems, Applications, and Products) Enterprise resource planning (ERP) software to manage their critical business functions, from finance and HR to supply chain and customer relations. However, the manual execution of SAP processes can be time-consuming, error-prone, and resource-intensive. This is where Robotic Process Automation (RPA) enters the picture. Robotic Process Automation (RPA) is the software solution which enables us to configure computer software, or a “robot” to simulate and integrate the actions of a human interacting within existing applications to execute a business process, like an automated virtual workforce. RPA, with its ability to mimic human interactions with digital systems, has revolutionized process automation by offering a scalable and efficient alternative to manual labor. UiPath, a leading RPA platform, has gained prominence for its user-friendly interface, robust capabilities, and seamless integration with various enterprise applications, including SAP. This paper aims to explore the symbiotic relationship between UiPath RPA and SAP, focusing on the strategies and benefits of automating SAP logistics processes. We will delve into the challenges organizations face when implementing SAP logistics process automation and how UiPath addresses these challenges. Additionally, the paper will highlight real-world use cases, demonstrating the tangible advantages of leveraging UiPath RPA in conjunction with SAP systems. Through a comprehensive examination of the integration between UiPath and SAP, this paper aims to provide a roadmap for organizations looking to embark on the journey of SAP logistics process automation. By understanding the intricacies, best practices, and potential pitfalls associated with this integration, enterprises can unlock new levels of operational efficiency and agility, ultimately driving business success in the digital era.

Recent literature highlights a growing trend towards automation in logistics processes, driven by the need for increased efficiency, reduced costs, and improved supply chain visibility. Automation solutions, including RPA platforms like UiPath, are being explored as valuable tools to streamline logistics operations.

The global logistics automation market size accounted for USD 58 billion in 2022 and is expected to hit around USD 196.01 billion by 2032 and is poised to grow at a compound annual growth rate (CAGR) of 13% during the forecast period 2023 to 2032 [1].

Studies often discuss the challenges associated with automating SAP logistics processes. These challenges include the complexity of SAP logistics modules, variations in data formats, and the need for seamless integration with other enterprise systems. Researchers emphasize the importance of RPA solutions, suchas UiPath, in addressing these integration challenges. In this paper we emphasize more on real time challenges faced when automating SAP processes with UiPath.

Challenge: Automation processes might encounter difficulties

when accessing or interacting with data stored on network drives.

Potential Solutions: Ensure that the robot has the necessary

permissions to access network drives. Consider using full UNC

paths instead of mapped drives.

Challenge: Regular password changes or expirations can disrupt

automation processes.

Potential Solutions: Implement a password management system

that updates credentials securely.

UiPath Orchestrator provides Credential Assets that can be

managed centrally.

Challenge: Lack of necessary authorizations in SAP for the robot

user can result in failed transactions.

Potential Solutions: Regularly review and update authorizations

for the robot user in SAP. Collaborate with SAP administrators to

ensure the required permissions are granted.

Challenge: SAP system upgrades can impact existing automation

scripts.

Potential Solutions: Regularly update and test automation scripts

after SAP system upgrades.

Stay informed about SAP release notes and plan automation

maintenance accordingly.

Challenge: Single Sign-On issues can interrupt the seamless

execution of automated processes.

Potential Solutions: Ensure that UiPath supports the SSO method

used in your SAP environment. Work with IT to address any SSO

configuration issues.

Challenge: Insufficient disk space on the robot machine can lead

to process failures.

Potential Solutions: Regularly monitor and manage disk space

on robot machines. Implement a process to archive or clean up

unnecessary data.

Challenge: SAP variants introduce complexity as they represent

different sets of input parameters.

Potential Solutions: Develop automation scripts that can handle

different variants. Regularly update scripts to accommodate

changes in variant configurations. It's important to note that

addressing these challenges requires a combination of technical

expertise, collaboration with IT and SAP administrators, and a

proactive approach to maintenance and updates. Regular testing

and monitoring are crucial to ensuring the continued success of

SAP automation with UiPath.

Scholars frequently delve into the capabilities of UiPath in the context of SAP automation. This paper cover UiPath's ability to navigate SAP GUI interfaces, interact with SAP Business Application Programming Interfaces (BAPIs), and handle various SAP transactions. The extensibility of UiPath for building custom activities tailored to SAP logistics modules is often highlighted.

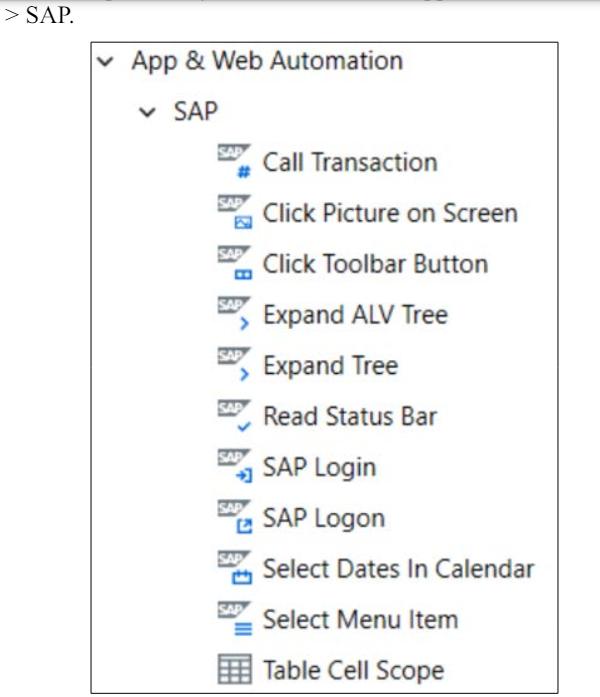

SAP Activities can be found in the UI Automation package. In the Activities panel, they can be found under App & Web Automation > SAP.

UiPath Studio is advanced automation software that gives everyone, from business users to advanced RPA developers, the right automation canvas to build great software robots and organizations the right governance tools to manage them all.

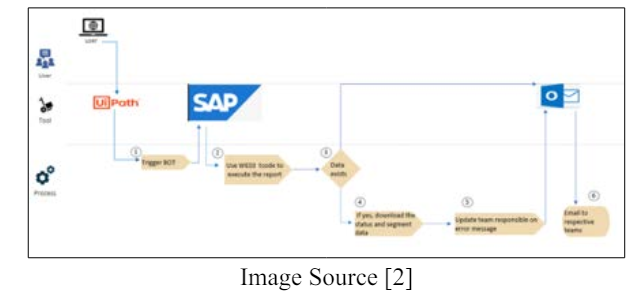

Below image illustrates high-level flow of SAP Automation using UiPath. This automation step is to download the data from SAP and consolidate that data for each in a spreadsheet. The data can be manipulated according to the required format and shared with the team responsible for fixing the IDOCs [2].

Below image depicts UiPath capabilities of automating activities & tasks in the Application software.

Daily Operations Reporting: UiPath is frequently employed for reporting purposes, assessing daily Key Performance Indicators (KPIs) in logistics operations, such as open order lines, processed shipments, in-process deliveries, open receivables, and goods received. These reports can be exported to a sequel server database or the cloud, presenting them in a dashboard for authorized management to validate and plan future operations. The rapid deployment capability of UiPath enabled the development of multiple logistics reports for the organization.

Mass Label Printing: UiPath's ability to automate SAP transactions and interact with SAP APIs allows the development of scripts for mass printing functions, such as labels and documents. This automation is more stable and faster than standard SAP mass execution tools like LSMW and SAP Scripting. Mass label printing automation is designed to print product and price labels for each item which is capable of scanning 2D barcodes with SAP integrated scanners to identify article codes and customer purchase prices.

Carrier Switch in Shipping: UiPath is often utilized to develop automation scripts for custom transactions in SAP. One such script involves switching carriers for shipping based on cost-effective rates negotiated by expeditors with carrier companies. This automation provides a reliable solution, making carrier switching more robust, accurate, and saving additional costs for shipments.

Labor Management: Warehouse Management in SAP has scope of extending labor management functionality which needs additional development, maintenance support and enhancement packages to integrate with own SAP HR or 3PL tools. However, UiPath ability to automate multiple operations reports within SAP such as number of order lines processed per user, number of packages processed per user, number of lines holding at dock stations, number of pallets jacked per user, number of packages nested etc., helped to evaluate individual performance as well as organization performance and fix the better compensation, promotions, calculating No. of man hours etc.,

Return Invoicing: UiPath's automation capabilities streamline SAP process flows and logistics operations, allowing the creation of scripts for Credit and Debit memos based on return shipments and reasons for return.

Sending ASN Information: Advanced shipping notification (ASN) to be sent to customer via ALE / Idoc interface when shipment process starts in SAP. UiPath bots are utilized to update and send Advanced Shipping Notification (ASN) information from SAP via ALE/Idoc interface, eliminating manual tasks and avoiding additional labor costs, time, and human errors. This has significantly reduced customer penalties and chargebacks.

Document Printing: Similar to label printing, a UiPath BOT is created to automatically print required documents such as Bill of Lading (BOLs), packing lists, and customs invoices when a warehouse associate scans a nested pallet from the scanner.

Testing: The UiPath integration with SAP Solution Manager enabled logistics team to obtain maximum value from their investments in SAP software by serving as a hub for all test management activities such as SAP Extended warehouse management (EWM) migration to S/4 HANA, All regular maintenance cycles, regression and non-regression tests, unit testing etc., and as the central information resource for all automation and testing processes.

• SAP EWM Picking, Put Away, Daily GI & GR Data Download

• EWM Data Import & Consolidation.

• Distribute Shipping and Receiving Deliveries from SAP ECC

to decentralize EWM with S/HANA.

• Creating Transportation Units in EWM S/4 HANA.

• Creating WAVEs in EWM S/4 HANA, etc.

• Posting Goods Issue in EWM

UiPath is frequently employed to automate order processing and fulfillment in SAP logistics. Bots can be programmed to receive and process orders, update inventory levels, and generate shipping documents. This accelerates the order-to-delivery cycle and minimizes errors in order fulfillment.

Automation using UiPath is applied to SAP logistics for tasks related to inventory management. Bots can perform regular stock checks, update inventory levels, and trigger reorder processes based on predefined thresholds. This ensures optimal inventory levels and reduces the risk of stockouts

Shipment Tracking and Documentation: UiPath RPA is often utilized to automate the tracking of shipments and generation of relevant documentation within SAP logistics modules. Bots can monitor the movement of goods, update shipping status in real-time, and generate shipping labels and documentation automatically.

Vendor and Supplier Communication: UiPath bots are employed to automate communication processes with vendors and suppliers within SAP logistics. This includes sending and receiving order confirmations, updating delivery schedules, and managing communication related to changes in logistics planning. Automated communication enhances collaboration and reduces manual intervention.

Benefits of Automation in SAP Logistics

Literature emphasizes the potential benefits of automating SAP

logistics processes using UiPath. These benefits include faster

order processing, real-time tracking of shipments, reduced errors

in data entry, and improved decision-making through enhanced

data accuracy. Cost savings and increased customer satisfaction

are also commonly cited outcomes.

Time Efficiency: Automation reduces the time it takes to execute repetitive tasks in SAP logistics processes. UiPath can swiftly navigate through SAP screens, extract data, and perform actions, leading to overall time savings. Robots can operate around the clock without human intervention. This ensures that critical logistics processes can be executed at any time, contributing to a more responsive and agile supply chain.

Accuracy and Error Reduction: UiPath ensures consistent and accurate data entry and retrieval within SAP. This reduces the likelihood of errors associated with manual data input, leading to improved data quality. Implementing error-handling mechanisms within UiPath can help identify and address issues promptly. This ensures that potential errors are caught and resolved before they escalate.

Cost Savings: By automating routine and time-consuming tasks, organizations can optimize their workforce, redirecting human resources to more strategic and value-added activities. Automation processes reduce the risk of manual errors that can lead to costly mistakes.

This, in turn, helps minimize the financial impact of errors on logistics operations.

Enhanced Compliance: Automation allows for the implementation of standardized processes across the SAP logistics workflow. This ensures that compliance with industry regulations and internal policies is consistently maintained. UiPath can be configured to provide detailed logs of actions performed during the automation process. This audit trail is valuable for compliance purposes and facilitates traceability

Scalability: UiPath robots can scale easily to handle increased workloads as the business grows. This scalability ensures that automation remains effective in managing larger volumes of logistics transactions. As SAP processes or logistics requirements evolve, UiPath workflows can be adapted and updated quickly to accommodate changes without significant disruption to operations.

Scalability: UiPath robots can scale easily to handle increased workloads as the business grows. This scalability ensures that automation remains effective in managing larger volumes of logistics transactions. As SAP processes or logistics requirements evolve, UiPath workflows can be adapted and updated quickly to accommodate changes without significant disruption to operations.

Customer Service and Satisfaction: Automation speeds up order processing and fulfillment in SAP logistics. This results in quicker response times to customer orders, improving overall customer satisfaction. By streamlining logistics processes, automation helps in reducing lead times, contributing to a more efficient supply chain and meeting customer expectations for timely deliveries.

Employee Empowerment: With routine and mundane tasks automated, employees can focus on more strategic and valueadded activities that require creativity, problem-solving, and human judgment. Automation implementation often involves upskilling or reskilling employees to work alongside robots. This can contribute to the development of a more skilled and versatile workforce.

In summary, this article on SAP logistics process automation using UiPath highlights the pivotal role of Robotic Process Automation (RPA) in elevating the efficiency and precision of logistics operations. By eliminating repetitive tasks in both SAP and Non-SAP systems, RPA significantly reduces manual efforts, expedites the shipping process, and lowers the error rate, ultimately leading to heightened customer satisfaction. The realworld use cases presented exemplify the tangible applications of UiPath in automating a range of logistics processes within the SAP ecosystem. These implementations contribute substantially to the optimization of supply chain management and overall business performance.