Author(s): Rubén Rodríguez Elizalde

Concrete is a structural material that can be destroyed as a result of varied nature actions. Among them, fire is important: fire is a physical action of great destructive capacity and, at the same time, fire is an accidental action. In general, a fire is a vandalism action or an accidental event, which can affect every structural element. Fire is frequently an aggressor agent for constructions, in general, and for concrete structural elements, in particular.

The fire attack is always complex. It acts over material made up of steel and concrete, with different behaviors and reactions to rising temperatures. Thus, it is necessary to study the alterations produced on the mechanical characteristics of the concrete, the alterations produced on the mechanical characteristics of the steel reinforcement and the alterations produced on the adherence between the steel and the concrete, and other phenomena such as the deformations imposed as a consequence. of the prevented expansions or the stresses produced by the temperature distribution gradients. This article aims to analyse the resistant capacity and the safety level of deterioration mechanisms, comparing real mechanisms and standard normative theoretical postulates.

Therefore, fire can cause very different damages, ranging from the simple staining caused by smoke and heat to its total destruction by combustion or by loss of resistance of its structure.

Here we will talk about fire on reinforced concrete structural elements, including civil engineering structures and building structures. In modern buildings, the danger of fire is lower than in old buildings. Modern buildings are currently built with non-combustible materials and with materials with greater fire resistance than those used in the old ones. And this despite the fact that many times we have skyscrapers [1]. In addition, construction techniques have evolved a lot. This has given rise to the fact that, when it is estimated that there may be a certain fire danger, the structural elements are protected with layers of insulating materials and the building is compartmentalized, both horizontally and vertically. This is done so that the fire does not spread from one area of the building to another.The Comité Euro-International du Béton (CEB, Euro-International Concrete Committee) and the Fédération Internationale de la Précontrainte (FIP, International Federation for Prestressing) have issued recommendations that have practically enjoyed a general consensus. They have been the basis of many fire protection standards that have appeared in a lot of countries [2.3].

The main objectives of fire protection and firefighting are to safeguard people and to reduce material losses to a minimum, both in buildings and in the materials or goods stored inside. Fire safety is never absolute: this must be made clear. When we talk about fire safety, we talk about reducing risks by adopting a series of measures. Each of these measures, by itself, is not enough; however, all of them together make it possible to achieve good safety against fire.The measures to be taken in the protection of a structure against fire can be of two types: active and passive [4]. A lot of countries have very comprehensive fire protection regulations in which the measures to be adopted are mainly based on the destination and height of the building. One of the most essential and common characteristics required by these standards is the fire resistance of construction elements, based on their stability and compartmentalization.

Losses caused by fires are a growing economic burden for a lot of countries. The loss of life, the families left homeless, and the loss of employment caused by the fires constitute a social burden that we cannot ignore. It is also true that the number of fires, and the economic impact that they entail, is decreasing because of the increasing importance that is being given to protection against them.Among the measures to combat such losses, the most effective is to build buildings with fire-resistant materials. Despite the fact that we can achieve rapid fire extinction by means of automatic detectors and extinguishers, if the fire resistance is low, we will not be able to avoid the temperature rise in some structural element. If this structural element is critical, it could cause the collapse of the building [1,3, 4].

A fire is an exothermic chemical reaction. However, during a fire, the materials absorb heat and expand, causing stress, deformation, and damage. The water produces sudden cooling and contractions that cause new damage to the materials; on the other hand, it can give rise to overloads on the floors, destroy waterproofing, etc., hence, sometimes, when water is not well used, it can be as destructive as fire itself, affecting the safety of the structural materials themselves. hot.

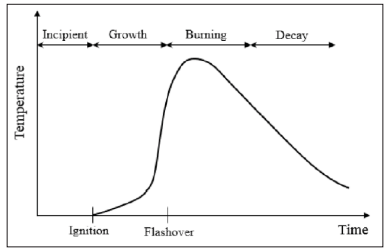

Figure 1: Development phases of a fire [10].

The most serious effects of a fire take place during the transition from the first (growth) to the second phase (burning) due to the rapidity with which the temperature rises, reaching, in some cases, values of 1250°C. In this transition, the generalized inflammation of the materials stored in the room where the fire occurs.The first phase (growth) of the fire is very conditioned to the reaction that the structure presents to the fire. In other words, the first phase is related to the ability it possesses to contribute to its development.

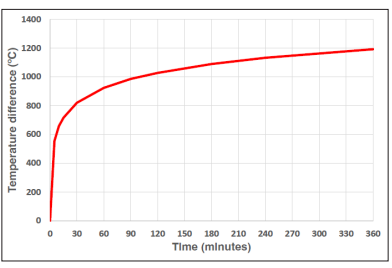

The ability of a material or structural element to remain, for a certain time, under the action of a fire, performing the functions for which it was designed gives us an idea of its resistance to fire. The fire resistance concept is applied to isolated materials or to elements formed with them, among which the floors, pillars, beams, walls, stairs, etc. deserve to be highlighted due to their structural function.The fire resistance of a material or element is measured conventionally and almost universally following the method standardized by the ISO R-834 standard [9]. The action of fire is simulated in this method following a theoretical program - pattern represented in Fig.2 The temperature rises in °C is done according to the logarithmic equation:

Figure 2: ISO standard curve that relates temperature and time (re-adaptation by the author) [9].

The duration of fire resistance of an element is determined by observing the variation of its mechanical resistance as a function of temperature, for which the element in question is subjected to the standard temperature - time program while it is subjected to the action of the conditions of use, that is, permanent or accidental applied loads for which it was designed, observing its deformations and the moment in which its failure occurs, that is, determining its inability to resist the expected loads [10].Likewise, the determination of fire resistance can be made against the tightness for which the element is subjected to the thermal program - standard and it is observed when the failure occurs, which will be revealed by the passage of gases or flames through cracks or cracks produced [7].

We can determine the fire resistance also against thermal insulation. In this case, the element to be tested is subjected to the program and the temperature rises on the face not exposed to the fire are observed. With this, we observe if they are within the preestablished limits so that the ignition of the materials that the element must protect does not occur [11].The results of the three tests have to be taken into account simultaneously when the element has to have resistant and protective functions. In this case, we will take the lowest value of the three times found as the result of the fire resistance. If the element only has a resistant function, it will suffice to determine the time resulting from the first test.

The fire resistance (Rf ) of the element is the time immediately below the duration observed in the chosen test. Its value will be between the values: 0.25, 0.50, 1.00, 1.50, 2.00, 3.00, 4.00 and 6.00 hours.Some countries complement the ISO fire resistance standard with

modifications based on the results of theoretical studies based on

statistical and experimental data in which the following have been

taken into account:

• The risk of fire due to the fuel load (nature, distribution), the

time of occupation, the ventilation openings, the importance

of the building, etc.

• The real resistance of the structure and its components,

considering the joints, compartmentalizations, loads to which

it is subjected, etc.

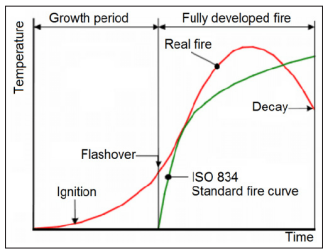

The ISO fire resistance standard can be considered basic and almost universally accepted as a standard temperature-time method. The results given by the ISO test do not usually correspond to those generated in a real fire (Fig. 3). For this reason, we need to establish an equivalence between the standard temperature - time relationship that we have seen and that has been normalized to have comparative results in the tests and the real temperature - time relationship that takes place in a fire. We must think that it can cause the maximum temperature to be reached in a shorter time. So, material can modify its properties sooner [7, 10].

Figure 3: Comparison of real fire and ISO 834 standard fire [15].

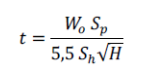

Many parameters influence the development of a real fire. Some of them [7, 8, 11] are:Kawagoe determined the precise time to reach the maximum temperature by means of the expression [13, 14]:

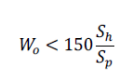

The English Fire Research completes Kawagoe's formula, by indicating that if

the temperature rise will depend only on the amount of fuel in the room, provided that the time does not exceed 30 min.

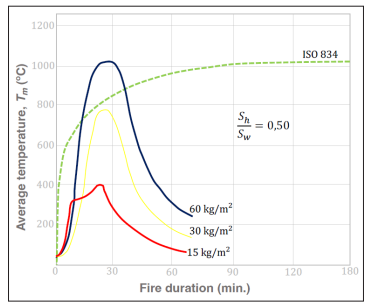

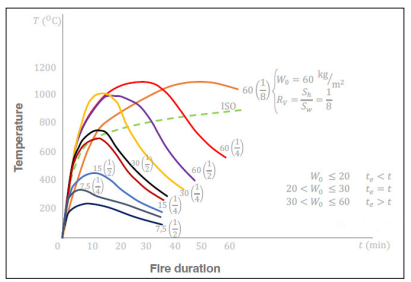

Fig. 4 and Fig. 5 show the temperature - time graphs for different unit calorific potentials, in kg of wood per m2 surface, for ventilation factors, that is, the relationship between the surface of open holes in walls and total surface of walls, of 0.25 and 0.60, comparing these curves in the same graphs with the ISO [9, 12].

Figure 4: Temperature - time graph, Sh /Sw = 0,25 (graphic adapted by the author [7]).

Figure 5: Temperature - time graph, Sh /Sw = 0,50 (graphic adapted by the author [7]).

As we can see in the graphs, when the ventilation increases, the maximum temperature decreases in the burned room, although the area of the curve increases.

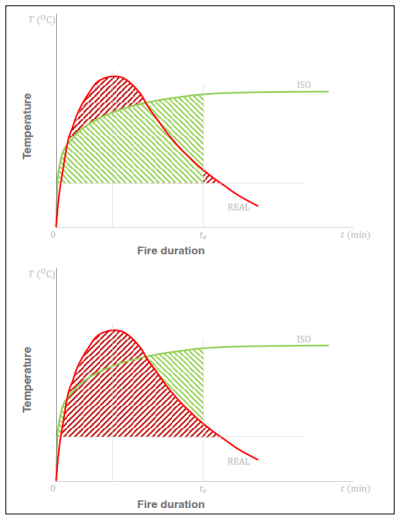

Here we also appreciate that the real curves are different from the theoretical or pattern. However, if we take into account that the transmission of heat between two points and the effect of fire is also proportional to temperature and time (in other words, to the area under the curves), we can find, through the equivalence of areas, the equivalent durations (the effect that the fire would produce, if it followed the thermal curve - pattern during the time te, or equivalent area time, Fig. 6).

Figure 6: Areas over difference between the pattern curve and the real curve of a fire (graphic adapted by the author [7]).

The time t in the Fig. 6 is the time for which the maximum temperature occurs in the real fire. In the case of concrete, the one corresponding to 300 °C is usually taken as the abscissa axis for determining these areas, because from this temperature is when the concrete begins to suffer alterations in its resistant behaviour.In tests carried out by the Fire Research Station for different calorific potentials and ventilation factors [15], it has been shown that there is a relationship between ventilation and duration of the fire (Fig. 7).

Figure 7: Influence of the calorific potential and the surfaces of the openings (Sh ) and of the wall (Sw) over the real temperature - time curves (graphic adapted by the author [7]).

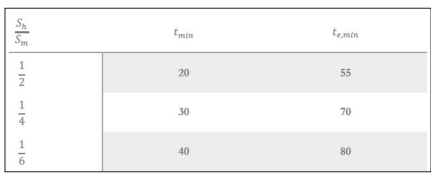

Comparing the real curve and the standard curve in Fig. 7, we can see that:Table 1: Minimum times required to reach the maximum temperature (t) and the equivalent temperature (t e ), depending on the ratio between the surface of the holes (Sh ) and the surface of the wall (Sw).

Fire resistance, as indicated above, is the time required for an element to collapse due to failure of mechanical resistance, sealing or thermal insulation, when subjected to a standard temperaturetime test, this time must correspond to the temperature equivalent at the instant the collapse takes place.

For the calorific potentials that have been seen previously and that do not exceed 60 kg/m2 of equivalent weight of wood, a fire resistance of 2 hours can be adopted, which gives a safety coefficient that can range between 1.5 and 2.0. The fire resistance of a structure must be proportional to the severity of the fires that can originate inside it.There are differences of opinion as to whether or not full protection against any possible fire should be provided in all cases. According to the British Building Regulations [16], a fully protected building, with complete and adequate fire resistance, is understood to be one that is built with non-combustible materials and that can withstand the total fire of what is stored inside.

Not all regulations are based on the total protection of the building and they accept a partial protection based on the concept of probability of fire risk and the possibility of variation of the fire resistance capacity of the structure.Although the experience we have on the behaviour of reinforced concrete structures against fire is limited, due to the difficulties presented by full-scale tests, we do have the experience gained in laboratory tests on concrete and steel materials and on isolated elements built with them [11]. We also have the experience of major fires in buildings built with this type of structure.

When concrete is attacked by fire, its components undergo significant changes. Thus, the free or capillary water included in the concrete begins to evaporate at 100°C (water boiling temperature), delaying its temperature rise, thanks to the latent vaporization heat. Between 200°C and 300°C the loss of capillary water is complete, but we still do not see any alteration in the structure of the hydrated cement. In this range of temperatures, the mechanical resistance of the concrete does not decrease appreciably either.From 300°C to 400°C, the loss of gel water from the cement occurs: at that moment, an appreciable decrease in resistance occurs and the first cracks appear in the concrete. At 450°C, part of the calcium hydroxide, coming from the hydration of the silicates, is transformed into lime oxide [11].

Not all aggregates have the same coefficient of thermal expansion. Because of this difference, around 600°C, the aggregates expand strongly and with different intensity, giving rise to internal stresses that begin to disintegrate the concrete. Many times, these expansions are increased by the structural transformations that occur in certain aggregates [17].

If we analyze aggregates from a mineralogical point of view, we have several important conclusions: siliceous aggregates, such as granite or gneiss, crack above 500°C as a consequence of the action produced by the volumetric increase experienced by quartz when change their structure with heat. Igneous aggregates, such as basalt, are not damaged by the action of heat. Natural lightweight aggregates, due to their porous structure and vitreous texture, behave very well against high temperatures. On the other hand, artificial lightweight materials, such as expanded clays or expanded slates, have a reaction to fire that is very similar to that of igneous aggregates, because the formation temperatures can be higher than the temperatures achieved in the fire.Limestone aggregates, along with light aggregates, are the least affected by fire due to their low coefficient of thermal expansion. The decomposition reaction of calcium carbonate to lime oxide is endothermic and, in addition, the carbon dioxide formed creates a thermal insulating film that surrounds these aggregates. All this makes limestone aggregates the most suitable against fire. It has also been verified that concretes in which the aggregates have a good granulometry and the aggregate/cement ratio is high perform better than those with poor aggregates and poor granulometry [17].

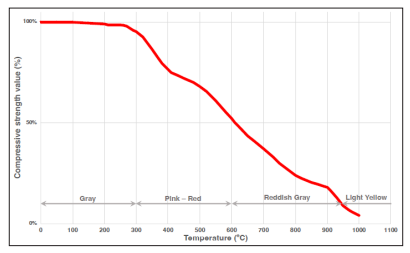

In the process of raising the temperature, concrete loses resistance and undergoes a series of colour changes that are more intense in siliceous aggregates than in limestone and igneous aggregates. This colour change remains after the fire, for days and even months. This change in colour can be hidden by the silt dragged by the water used to extinguish the fire. This colour change is important because it can be an index to determine the loss of resistance and the changes in conditions that the concrete has experienced (Fig. 8).At 200°C, the concrete is grey and does not present an appreciable change in its conditions or in its compressive strength. At 300°C, the concrete experiences a decrease that can be estimated at 10%; at this temperature, the colour of the concrete turns pinkish due to the loss of water from the iron salts present in the aggregates. From 300°C to 600°C, the compressive strength of the concrete decreases by 50% and the modulus of elasticity by 80%, turning the colour of the concrete from pink to red. Between 600°C and 950°C, the color changes back to grey with reddish spots; this tone is index of friability and high-water suction. At this last temperature, the strength of the concrete is very low. Already from 950°C to 1,000°C, the colour changes to orange-yellow, and the concrete begins to sinter. Between 1,000°C and 1,200°C, the concrete sinters and its color turns light yellow, its resistance being completely null (Fig. 8).

Figure 8: Influence of temperature on the compressive strength of concrete (author's adaptation).

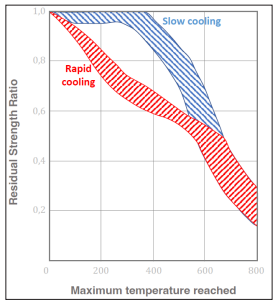

If the concrete temperature has not exceeded 500°C, it may experience rehydration after the fire, which can make it recover up to 90% of its initial resistance after one year; In any case, the resistance gain when cooling is small and depends a lot on the speed at which the cooling has been done. (Fig. 9).

Figure 9:

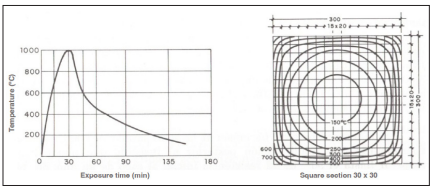

Residual strength of concrete on cooling (graphic adapted by the author [7]). In favour of the good behaviour of concrete against fire, the low coefficient of thermal conductivity that it possesses counts and the fact that this coefficient decreases as the temperature increases to values that reach a third of the initial value. Because of this, the temperature difference between the surface of a piece or element and the core of the same piece or element is significant, provided that the fires do not last very long.Fig. 10 shows the isotherms for a 0.30 x 0.30 m concrete column, subjected to a fire with an equivalent wood load of 60 kg/m2 and a ventilation factor of 0.30, content in an enclosure with high thermal insulation. Next to the isotherm graph, the real temperature - time curve is represented. We can observe that only the external 5 cm register temperatures above 300°C, that is, temperatures that alter the mechanical characteristics of the concrete. It occurs despite the fact that the temperature of the gases in contact with the surfaces of the support can be as high as 1,000°C. This is equivalent to a 2-hour ISO standard fire duration (Fig. 2) [9].

Figure 10: Isotherms in a 30 x 30 cm column, subjected to the left temperature-time curve [8].

As we have seen, the determination of the colour of the concrete in the area of the fire is very important: the colour of the concrete indicates the temperature reached and this data, in turn, the resistance that the concrete has lost. To be able to observe the colour of the concrete after a fire, many times we have to make a cut or cause a small impact that makes a slab jump. With this we can see the true colour of the concrete, behind the black envelope caused by the fire. In the Fig. 11, we can see two chips on the bottom flange of a beam, revealing the grey colour of the concrete. It means that there has been no loss of strength.

Figure 11: Slight chipping at the bottom flange of a beam, revealing the grey colour concrete (photograph by the author).

Obviously, a civil engineering structure is not the same as a building structure. In general terms, the structural elements of a building will be more accessible than those of a civil work. To this end, the incorporation of drones to carry out inspections is very interesting [18]: the drone can approach visible elements that are difficult to access or dangerous, not only because of accessibility but also because of the structural uncertainty that a fire can cause (Fig. 12).

Figure 12: Multi-rotor drone approaching the beams that had suffered a fire, to be able to contemplate what is collected in the Fig. 11 (photograph by the author).

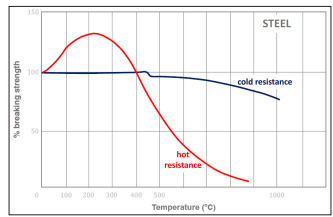

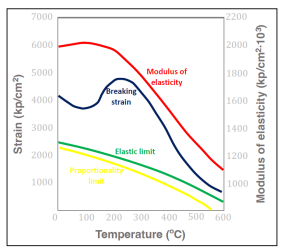

The mechanical properties of steels decrease with increasing temperature and this effect must be taken into account in structures subjected to the action of fire and in which steel is involved as a resistant material [19].Fig.13 shows the tensile strengths of a soft steel at different temperatures, as well as those it acquires after cooling. Fig.14 shows the variations of some characteristics of a soft steel with temperature.

Figure 13: Influence of temperature over steel tensile strength (graphic adapted by the author [7]).

Figure 14: Temperature influence over ordinary steel (graphic adapted by the author [7]).

We can observe that a mild steel, heated to a temperature between 400°C and 800°C and subsequently cooled slowly in air, presents a final resistance that varies little with respect to the initial one. At temperatures above 800°C, the steel shows a marked loss of strength on cooling. With higher temperatures, and around 1,000°C, we have reductions in tensile strength of up to 25% [7, 19, 20].When we make a repair project, the steel that we must consider is the one that has recovered part of its initial resistance due to being cold. However, knowing the behaviour of steel at high temperatures is essential to understand certain types of damage that appear in some structural elements, such as large deflections and deformations suffered by beams or slab floors.

Fig. 14 shows how, at temperatures above 400°C, the tensile strength of a steel drops rapidly and how at 800°C the remaining strength is very low. These marked changes are caused by the crystalline alteration that the steel undergoes above 100°C, giving rise to an increase in the size of the grains and a decrease in the breaking stress. Above, approximately, 728°C, depending on the carbon content of the steel, the transformations are more energetic when passing the ferrite and pearlite to austenite.

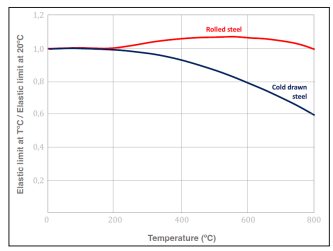

Just as the breaking stress in some steels increases up to 200°C and then decreases, their elastic limit decreases as soon as the temperature rises. It is very important to know that mild steels and laminated natural hardness steels practically recover their resistance capacity when they cool down, provided that the temperatures have not exceeded the limits indicated above. However, the colddrawn steels, existing in old structures, characterized by their conventional elastic limit due to remaining deformation of 0.2%, when they are subjected to the action of high temperatures, they transform into the original steels, that is, they return to have the properties that they possessed before the stretching treatment; therefore, these steels do not recover their initial strengths when they cool down (Fig. 15).

Figure 15: Strength recovery curve of a cold drawn steel (graphic adapted by the author [7]).

In prestressed steels, the action of heat is even more critical because these are hardened by drawing and are thermally treated, which causes them to irreversibly lose their characteristics due to the action of fire.

In tests carried out to evaluate the resistance of prestressed concrete against fire, it has been observed that the failure or breakage of the steel is imminent for temperatures slightly above 400°C, in which the limit stress of these high tensile strength steels is almost halved.We call the critical temperature of a steel that temperature for which its elastic limit takes the value of the working stress.

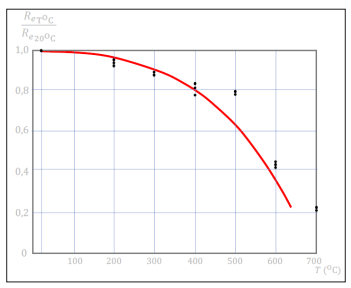

In Fig. 16 we can observe the variation of the relative elastic limit of a B400S steel (elastic limit 400 N/mm supernatant 2) with temperature. The main factors influencing the temperature rise of steel in reinforced concrete are:

Figure 16: Elastic limit variation with temperature, on a steel with 400 N/mm2 elastic limit (graphic adapted by the author).

When, due to the effect of the temperature rise produced by a fire, the mechanical resistance of a structural element is equal to the tensions produced by the actions to which it is subjected, its resistant reserve or safety coefficient disappears, and the element will no longer be stable and exhaustion will occur. The temperature at which this occurs is called the critical temperature of the element.A reinforced concrete structural element is made up of two different materials: concrete and steel; therefore, the behaviour of these two materials working together against fire must be considered [11, 21, 22]. If we consider that of the materials considered the most sensitive to fire is steel, we will see the importance of protecting it through appropriate concrete coatings, sometimes complemented with layers of thermal insulation.

Apart from the actions that fire exerts on concrete and steel, considered separately and that we have already analysed, there are other even more complex actions that act on reinforced concrete. These are actions that, furthermore, become more complicated when reinforced concrete forms structural elements and these elements are joined together, as occurs in any structure [23].In reinforced concrete, the temperature effect rise on concrete and steel does not usually produce stresses because the coefficients of thermal expansion of the two materials are practically the same (1.2 • 10-5 m/m. °C) within normal ranges of ambient temperatures.

However, when the temperatures are high, both coefficients are far apart, with the steel coefficient being thirty times higher than that of the concrete and, therefore, producing significant stresses that can cause the coatings to flake (Fig. 17). If it happens, the steel is directly exposed to the action of heat, which decreases its elastic limit and its breaking stress, resulting in failure if its temperature approaches the critical temperature, that is, approximately 500°C for steels. soft [24].

Figure 17: Semi-discovered steel reinforcement as a consequence of the loss of coating, in the structure of the Fig. 11 (photo by the author, taken with a drone).

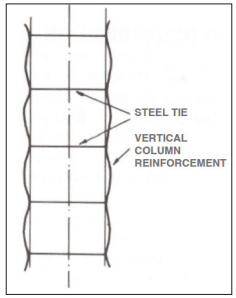

In the case of columns, the bars [25, 26] expand, sag and cause the coatings to skip, causing their resistance to decrease so much that they may collapse (Fig. 18).

Figure 18: Column steel bars buckled by the fire action [7].

Knowing the fire behaviour of concrete and steel, the new stressstrain laws of the materials can be determined and how the adherence between them is affected, as well as the new momentcurvature diagrams.

Another aspect to consider is the loss of adherence between the concrete and the steel due to the effect of temperature rise. The thermal effects on adhesion have been studied by Hertz through hot "pull-out" tests. The results obtained follow a law very similar to that of variation of the compressive strength of concrete up to 300 or 400°C. Above these temperatures, adherence decreases more than compressive strength, so that the bond stress- compressive strength ratio drops to 65% for 400°C and 35% for 600°C. Between 600 and 800°C the adherence practically disappears.The loss of adhesion of steel bars is influenced by the temperature and the diameter of the bars. The smaller the diameter of the bars, the lower the loss of adhesion. The compressive strength of the concrete, the type of aggregate used in the manufacture of the concrete, the dimensions and the section of the piece, etc. also have an influence. The Steel tie also condition grip, improving it.

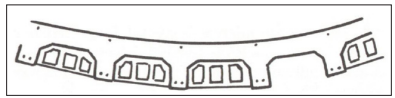

Floor slabs and slabs are exposed to flames on their lower face, so that heat tends to accumulate in it, producing significant dilations in it that cause the slab or slab to curve and vaults to detach, in the case of the slabs (Fig. 19) and the occurrence of subsidence that causes large circular or elliptical holes in the slabs centre.

Figure 19: Slab floor bending deformation due to the heat effect [7].

The action of fire on concrete causes evaporation of capillary water between 100°C and 300°C. At this temperature, the complete disappearance of this capillary water occurs, although no significant strength losses have yet occurred. The water contained in the cement gel is lost at temperatures ranging between 300°C and 400°C: thus, at these temperatures the resistance decreases and the first cracks appear.

From 450°C, the calcium hydroxide is transformed into oxide (quicklime) and already towards 600°C a strong phenomenon of expansion of the aggregates takes place, disintegrating the concrete and decreasing its resistance. It is interesting to note that, from this point of view, limestone aggregates are the least sensitive to the action of fire because they have lower thermal conductivity.Another consequence of the action of fire is the "thermal shock" it produces. This produces dilations on the face in contact with the action of the fire and expansion of the hot gases. Consequently, compatibility stresses appear which, although self-balancing, reach such a value in traction that they end up causing the concrete to break.

Throughout this article we have analysed the relationship between the reduction in the compressive strength of concrete and the temperature of the gases. We have also seen that color is an indicative data, posteriori, of the temperature reached in the concrete and, consequently, of the loss of resistance that may have occurred. Finally, if the temperature of the concrete has not exceeded 500°C, the concrete can be rehydrated. If achieved, concrete can recover up to 90% of its initial strength capacity after one year.On the other hand, the fire action over reinforcing steel is manifested in a faster expansion than over concrete that surrounds it and in a bigger loss of resistant capacity. In the article, we have analysed the evolution of the resistance capacity of steel with respect to temperature. We have seen that a mild steel, heated to a temperature between 400°C and 800°C and then slowly cooled, barely loses its strength capacity, while the hot tensile strength falls much faster. It is due to the fact that, starting at 400°C, the steels begin to see their crystalline composition altered, increasing the size of the grains and reducing the breaking stress.

If the temperature of the steel does not exceed 700°C, the resistance of mild steels (smooth round) and natural hardness recover to values similar to the initial ones. This is especially the case if the cooldown has been slow. On the other hand, in cold-formed steels (steels widely used in structures from the 1960s and 1970s), crystalline alteration can reduce their resistance capacity by up to 40%. In prestressed steels, fire causes irreversible alteration of its characteristics. This forces us to be very careful when evaluating structures in which the steel of the tendons has been affected.

Another very important aspect, revealed in the fires produced in concrete structures, is the loss of adherence between concrete and steel. This is due precisely to the difference in conductivity between the steel bars and the concrete. As a result, differences in temperature are produced between both materials and, consequently, different deformations are also induced. This brings with it the appearance of compatibility stresses at the steel-concrete interface which, if the temperature is high, can cause breakage due to adherence and detachment of the coating. This process is accelerated by the contraction that occurs as a result of the sudden cooling due to the action of the water applied to suffocate the flames. The loss of the steel coating is also one of the typical manifestations of fires. Pathology studies of structures damaged by fire require high specialization, especially to calculate the residual resistant capacity after the fire, according to the experimental evaluation of the situation. In many cases, although the appearance is alarming, it is possible to recover the structure, even with relatively simple rehabilitation processes.