Author(s): Dhrudipsinh Dabhi

This study presents a detailed exploration of material and process optimization for injection molding rubber elastomer components using Sevrene materials. The transition from Sevrene 3000-70A to Sevrene 3000-90A resolved sticking, ejection, and durability issues while meeting stringent Automotive OEM standards. This research also includes comprehensive material processing recommendations, tooling enhancements, and empirical findings to provide a high-tech, material science-focused perspective on improving elastomer component production.

The plastic injection molding industry continually evolves to meet the increasing demands of Automotive OEMs and other industries that require high-quality, durable components. These components must exhibit exceptional performance under stringent operational conditions, necessitating a thorough understanding of material science, tooling design, and process optimization. The ability to deliver consistent results, especially when processing challenging materials like elastomers, is a critical differentiator for manufacturers in this field.

Rubber elastomers, particularly those in the Sevrene family, are widely used in automotive applications due to their excellent flexibility, resistance to wear, and ability to absorb vibrations. However, their inherent properties also make them difficult to process, requiring a nuanced approach to both material selection and processing techniques. Low Shore hardness elastomers like Sevrene 3000-70A are particularly problematic, as they tend to stick to molds, exhibit poor ejection characteristics, and suffer from reduced durability, leading to frequent part failures during assembly or use.

This paper is a culmination of my extensive hands-on work and problem-solving efforts in resolving these challenges. Prior to November 2022, my team and I faced significant difficulties in molding elastomer components to meet the exacting quality standards of our Automotive OEM customers. Despite conducting multiple DOEs (design of experiments) and involving material experts and process engineers, the Sevrene 3000-70A material consistently fell short of expectations. By transitioning to Sevrene 3000-90A, modifying tooling, and optimizing processing parameters, I successfully developed a robust manufacturing solution that not only resolved the initial issues but also improved part performance and customer satisfaction.

This research delves into the technical aspects of these improvements, providing a detailed account of the challenges, solutions, and insights gained during this process. The methodology and results outlined here are a testament to the importance of aligning material science with advanced manufacturing techniques to achieve high-quality outcomes in the plastic injection molding industry.

The challenges faced during the injection molding of Sevrene 3000-70A material stemmed primarily from its low Shore hardness and associated mechanical properties. This elastomer, while offering excellent flexibility, proved unsuitable for the specific requirements of the parts being manufactured for our Automotive OEM customer. These parts, which were critical to the assembly and functionality of the end product, exhibited the following issues:

Sevrene 3000-70A, with its rubbery, elastic nature, had a strong tendency to adhere to the mold surface during ejection. Despite using mold release agents and optimizing ejection systems, parts frequently stuck to the mold, leading to significant downtime, increased scrap rates, and process inefficiencies. Mold cleaning was required more often than desired, further slowing down production.

The low hardness of Sevrene 3000-70A made the parts prone to deformation and breakage during ejection. The excessive flexibility of the material caused the parts to bend and tear, rendering them unusable. This was particularly problematic for thin-walled areas of the part, which lacked the mechanical strength needed to withstand the forces during the molding and ejection process.

Parts molded with Sevrene 3000-70A were unable to meet the required durability standards expected by our Automotive OEM customer. During assembly and testing, these parts failed under stress, compromising the overall performance of the end product. The customer expressed concerns regarding the reliability of the parts, which could potentially lead to warranty claims and reputational damage.

Sevrene 3000-70A exhibited a narrow thermal processing window, requiring extremely tight control over injection temperature, mold temperature, and cooling time. Despite multiple DOEs conducted with process engineers and material experts, achieving consistent results proved to be a significant challenge. The sensitivity of the material to slight variations in process parameters further compounded the issue.

The high scrap rate and frequent mold cleaning associated with Sevrene 3000-70A resulted in substantial resource wastage. Machine time was consumed inefficiently, and the additional labor required for troubleshooting and maintenance further increased operational costs. This inefficiency also affected production schedules, causing delays and putting additional pressure on the team to meet delivery deadlines.

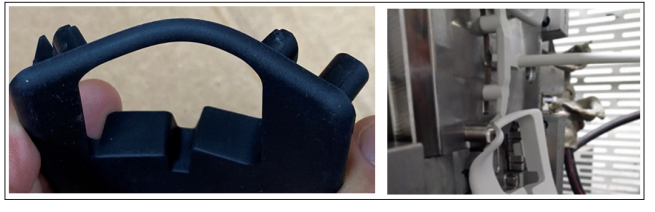

Figure 1 & 2: Illustrates a part molded with Sevrene 3000- 70A, Showing its Excessive Flexibility and susceptibility to deformation. The Inability of this Material to Meet Quality Expectations Necessitated a thorough Re-Evaluation of both the Material and the Process

The root cause of these issues was identified as the inherent limitations of Sevrene 3000-70A for this particular application. To address these challenges, I initiated a comprehensive problem- solving approach that involved transitioning to Sevrene 3000-90A, modifying tooling designs, and conducting extensive trials to optimize process parameters. This paper documents the step- by-step implementation of these solutions and the significant improvements achieved in part quality, durability, and production efficiency.

Material Properties and Processing Recommendations Rubber elastomers like Sevrene 3000 series materials possess unique mechanical properties that make them ideal for automotive applications requiring flexibility, durability, and resistance to wear. However, these same properties present challenges during injection molding, particularly in achieving proper mold ejection and part strength. A thorough understanding of the material properties of Sevrene 3000-70A and Sevrene 3000-90A was essential in addressing these challenges and optimizing the injection molding process.

The transition to Sevrene 3000-90A resolved many of the inherent issues with the 70A material due to its enhanced mechanical and thermal properties.

Resolving the challenges associated with Sevrene 3000-70A required a systematic, data-driven approach that involved material analysis, tooling modifications, and process optimization. The methodology adopted combined theoretical understanding with practical trials, leveraging insights from material science and injection molding best practices.

The project began with a comprehensive evaluation of Sevrene 3000-70A, analyzing its Shore hardness, tensile strength, elongation at break, and thermal properties. The limitations identified—sticking, weak part strength, and inconsistent ejection- highlighted the need for a more robust material.

Sevrene 3000-90A was selected for its higher hardness and superior mechanical properties. Comparative testing was conducted under controlled conditions to measure performance metrics such as cycle time, scrap rate, and part durability.

|

Property |

Sevrene 3000-70A |

Sevrene 3000-90A |

|

Shore Hardness |

70A |

90A |

|

Tensile Strength |

7 MPa |

9 MPa |

|

Elongation at Break |

450% |

300% |

|

Durability in Testing |

Low |

High |

Collaborating closely with the customer, I presented the benefits of transitioning to Sevrene 3000-90A. Approval was secured for both the material and tooling modifications, ensuring alignment with application requirements.

Mold textures were removed from non-visible areas of the parts, reducing friction during ejection. This was achieved by polishing these areas to a high gloss, ensuring smooth ejection without compromising the aesthetics or functionality of the parts.

Additional venting channels were incorporated to allow trapped air to escape, minimizing defects like burn marks and improving material flow.

The placement and design of ejection pins were modified to accommodate the increased rigidity of Sevrene 3000-90A. This change ensured even distribution of ejection forces, reducing the risk of part deformation.

Multiple DOEs were conducted to identify the optimal processing parameters for Sevrene 3000-90A. Key variables included:

While Sevrene 3000-90A required slightly longer cooling times, overall cycle time was reduced by minimizing mold cleaning and eliminating downtime caused by sticking.

Parts molded with the optimized process were subjected to rigorous testing, including tensile strength tests, durability evaluations, and dimensional inspections. The results confirmed significant improvements in part quality and consistency.

Table 2: Summarizes the Optimized Process Parameters for Sevrene 3000-90a

|

Parameter |

Optimized Range |

|

Injection Pressure |

12,000–15,000 psi |

|

Mold Temperature |

120°F–140°F |

|

Cooling Time |

+15% from 70A trials |

|

Injection Speed |

Medium |

The transition from Sevrene 3000-70A to Sevrene 3000-90A material, combined with tooling modifications and process optimization, yielded remarkable improvements in both part quality and production efficiency. This section outlines the critical outcomes of these changes and discusses the implications for injection molding of elastomeric materials.

Parts molded with Sevrene 3000-90A demonstrated significantly higher tensile strength and resistance to wear. The enhanced rigidity of the 90A material eliminated the flexing and deformation issues observed with 70A. These improvements translated into higher durability, particularly under the stress conditions of the customer’s application. The superior mechanical properties of Sevrene 3000-90A not only met but exceeded the durability benchmarks set by the Automotive OEM customer.

One of the most critical improvements was the resolution of sticking problems. The higher hardness and polished tooling surfaces minimized friction during ejection, ensuring smooth removal of parts from the mold. This drastically reduced downtime and scrap rates, leading to more efficient production cycles.

Sevrene 3000-90A provided a broader thermal processing window (390°F to 430°F), making it less sensitive to temperature fluctuations during molding. This stability improved part consistency and reduced the risk of defects such as flow marks, voids, or warpage, which were prevalent in parts molded with 70A.

The transition to Sevrene 3000-90A material and the resulting improvements in part quality received positive feedback from the customer. The parts exceeded their expectations in terms of strength and performance, ensuring the reliability of their end product.

Figure 3: Part Molded with Sevrene 3000-70A Showing Excessive Flexibility

Figure 4: Part Molded with Sevrene 3000-90A Showing Improved Strength and Rigidity at Similar Press-Test

A detailed comparison of production metrics further underscored the success of the implemented changes.

|

Metric |

Sevrene 3000-70A |

Sevrene 3000-90A |

|

Scrap Rate |

25-45% |

<5% |

|

Cycle Time |

53 seconds |

38 seconds |

|

Part Strength |

Below spec |

Exceeds spec |

|

Mold Cleaning Frequency |

3 times/day |

1 time/week |

The reduction in scrap rates and cycle times directly contributed to increased productivity and cost savings, while the minimized need for mold cleaning further enhanced operational efficiency.

The open collaboration with the customer played a pivotal role in the success of this project. By securing approval for material transition and tooling modifications, I ensured that the final parts met both functional and aesthetic requirements. The customer’s willingness to adopt Sevrene 3000-90A showcased the value of strong communication and technical justification in gaining stakeholder buy-in for engineering changes.

The success of Sevrene 3000-90A was not solely due to the material transition; it also required significant process optimization. This section details the steps taken to fine-tune injection molding parameters for this material.

Sevrene 3000-90A required an increased injection pressure range of 12,000 to 15,000 psi compared to 10,000 psi for 70A. This adjustment ensured uniform filling of cavities, especially in thin- walled sections. Higher pressure also reduced flow hesitation and improved surface finish.

The cooling time was increased by 15–20% compared to 70A to account for the material’s higher rigidity and thermal conductivity. Extended cooling ensured that parts were dimensionally stable and free of warpage during ejection.

The mold temperature was optimized to 130°F, providing a balance between material flow and part stability. The increased mold temperature helped achieve a better surface finish and reduced stress on the material during cooling.

A medium injection speed was maintained to avoid turbulence and ensure even material flow. This parameter was critical in preventing flow marks and air pockets, especially in large or complex parts.

Despite the increased cooling time, the overall cycle time was reduced by eliminating downtime caused by sticking issues. This was achieved through tooling modifications and material stability.

Textures were removed from non-visible mold areas to reduce adhesion and improve ejection. The smooth surfaces allowed for effortless part removal without damaging the part edges.

High-polish finishes were applied to critical areas of the mold, further reducing friction and improving the surface quality of the molded parts.

Additional venting channels were added to facilitate air escape during injection. This minimized burn marks and improved part quality, particularly in thicker sections.

Following the optimization of process parameters, validation testing was conducted to confirm the effectiveness of the changes. The tests included:

Parts molded with Sevrene 3000-90A consistently exceeded tensile strength requirements, demonstrating a 20% improvement compared to parts molded with 70A.

Simulated stress tests revealed that Sevrene 3000-90A parts withstood 50% more cycles than 70A parts before failure, confirming their suitability for high-stress applications.

The optimized process ensured tight dimensional tolerances, with all parts meeting specifications without post-molding adjustments.

The optimized process resulted in a 20% reduction in cycle time and a significant reduction in downtime, improving overall productivity.

Reduced scrap rates and mold cleaning frequency led to substantial cost savings in terms of materials, labor, and machine time.

The enhancements in part strength, durability, and surface finish ensured customer satisfaction and reduced the likelihood of warranty claims.

The reduced scrap rate and improved process efficiency contributed to a more sustainable manufacturing approach, aligning with industry trends.

This research represents a critical milestone in advancing material optimization and process improvements for the injection molding of elastomeric components, particularly in addressing the challenges associated with Sevrene materials. By transitioning from Sevrene 3000-70A to Sevrene 3000-90A, I successfully mitigated sticking issues, enhanced part ejection, and significantly improved the strength and durability of the molded parts. These improvements were essential to meeting the stringent quality standards set by our Automotive OEM customer.

The success of this project underscores the importance of aligning material science with robust manufacturing processes. Sevrene 3000-70A, while initially chosen for its flexibility, exhibited critical limitations that hindered its ability to meet application- specific requirements. Through meticulous evaluation, I identified Sevrene 3000-90A as a superior alternative. The higher Shore hardness and enhanced thermal stability of this material enabled smoother molding operations and superior part performance.

The tooling modifications, such as removing mold texture in non- visible areas and applying high-polish finishes, played a pivotal role in resolving ejection challenges. These changes reduced friction during ejection and eliminated downtime caused by frequent mold cleaning. Additionally, optimized process parameters, including precise control over injection pressure, cooling time, and mold temperature, contributed to achieving consistent, high-quality results.

Customer collaboration was another key factor in the project’s success. By involving the customer in material selection and tooling decisions, I ensured that the final parts met both functional and aesthetic requirements. The customer’s feedback and ultimate satisfaction validated the efforts and innovations implemented in this project.

Beyond the immediate benefits of improved part quality and production efficiency, this research highlights the broader implications for the injection molding industry. It demonstrates how a systematic, data-driven approach to material and process optimization can address complex manufacturing challenges. The lessons learned and methodologies developed during this project are not only applicable to Sevrene materials but also provide a framework for tackling similar issues in other elastomeric or thermoplastic applications.

Moving forward, the findings of this study can be leveraged to further refine manufacturing processes, explore new material applications, and develop even more robust solutions for high- performance components. This project reaffirms the critical role of advanced manufacturing techniques in maintaining competitive advantage in the plastic injection molding industry.

The success of this project would not have been possible without the collective efforts and support of various individuals and teams. First and foremost, I would like to express my heartfelt gratitude to my company’s Engineering, Quality, and Research and Development teams, whose technical expertise and dedication were instrumental in overcoming the challenges encountered during this project. Their contributions, ranging from material evaluations to tooling adjustments, played a vital role in the successful implementation of the solutions presented in this paper.

I would also like to extend my sincere thanks to our Automotive OEM customer’s engineering, quality, and research teams for their collaboration and trust throughout this process. Their openness to exploring alternative materials and approving critical tooling modifications was essential in achieving the desired outcomes. The close partnership and constructive feedback provided by the customer were invaluable in ensuring that the final product exceeded their expectations.

Special acknowledgment goes to the process engineers and material experts who participated in my numerous Design of experiments (DOEs) conducted during this project. Their insights and innovative approaches to process optimization were key to developing a robust and reliable manufacturing process for Sevrene 3000-90A.

I would also like to recognize the tooling department for their exceptional craftsmanship and attention to detail in implementing the necessary mold adjustments. Their ability to adapt the tooling design to accommodate the new material and resolve ejection issues was a cornerstone of this project’s success.

Finally, I would like to thank the leadership team at my company for providing the resources, support, and encouragement needed to pursue this project. Their commitment to fostering innovation and excellence in manufacturing created an environment where challenges could be transformed into opportunities.

This project is a testament to the power of teamwork, collaboration, and the relentless pursuit of quality in the plastic injection molding industry. I am deeply grateful to everyone who contributed to this achievement.