Author(s): Eethar Thanon Dawood* and Tamara Waleed Ghanim

In the present paper the behavior of mortar reinforced with polypropylene fibers was studied. Different percentages of polypropylene fibers such as 0, 0.2, 0.4, 0.6 and 0.8% as volumetric fractions were used. Different properties which are flowability, density, compressive strength, flexural strength and splitting tensile strength were evaluated for all mix combinations. The experimental results indicated that a reduction in flowability was obtained with increased polypropylene fibers content. Besides, it can be concluded that the incorporation of polypropylene fiber may significantly reduce the density of mortar. The use of low volume fraction of polypropylene fiber improves the mechanical properties of HPM. Thus, the use of 0.2% of such fiber increases compressive strength by about (4-10%), at various ages.

Mortar is one of the most materials used in construction, despite its low behavior in tension. This handicap is the most main cause of cracking which can damage its durability and its appearance; one of the solutions proposed to possess these cracking is to use of fibers reinforced cementitious material. Adding fibers to a matrix increases the energy absorbing capability of hardened concrete, makes it more suitable for use in structures subjected to impacts loads [1].

The strengthening effect of fibers in the cementitious materials is attributed to the bridge effect among the crack propagating. The three main mechanisms of failure of fibers are fiber pullout, fiber rupture and fiber/matrix debonding. The properties of the fibers play an important role in determining the dominant mechanism of failure, and subsequently on the macroscopic behaviour of the cracked fiber reinforced mortar [2-4].

Synthetic fibers have recently become more valuable as reinforcements for cementitious materials. Recently, most attention has been dedicated to the adoption of polymeric fibers, due to their advantages over the metallic ones with special regard to chemical stability, lightness and workability. Several authors have studied the efficiency of polymeric fibers as reinforcing materials for concrete as polyethylene (PE), polypropylene (PP), acrylics (PAN), poly(vinyl alcohol) (PVA), polyamides (PA) and polyester (PES). Showed that among different fibers, PP fibers were the most efficient. Polypropylene (PP) fibers have numerous properties that make them suitable for incorporation to concrete: low cost, ductility, ease of dispersal and good anchoring capacity. Polypropylene fibers do not corrode, are thermally stable (high melting point), chemically inert and very stable in the alkaline environment of concrete [5-10].

The objective of this study is to determine the basic characteristics of mortar reinforced with polypropylene fiber in terms of flowability, compressive strength, flexural strength and split tensile strength. The effect polypropylene fiber was studied in different volumes fraction at 0%, 0.2%, 0.4%, 0.6% and 0.8%.

Cement: Ordinary Portland cement (OPC) type I from Badoosh manufacture (Nineveh/Iraq) was used in this study, the characteristics and chemical compositions of cement according to IQS: 5/1984 are shown in Tables 1 and 2 [11].

Table 1: Characteristics of Ordinary Portland cement| Test | Produced cement | IQS : 5/1984[11] |

|---|---|---|

| Initial setting time | 130 | Min. 45 minute |

| Final setting time (minute) | 155 | Max. 600 minute |

| Fineness (Blain cm2 /g) | 2636 | More than 2300 |

| Compressive strength

3 days, N/mm 2 7 days, N/mm2 |

23.0 30.0 | ≥15 MPa ≥ 25 MPa |

| Oxide | Content of OPC (%) | Limit of Iraq specification No.5/1984[11] |

|---|---|---|

| CaO | 62.20 | - |

| SiO 2 | 21.31 | - |

| Al 2 O 3 | 5.89 | - |

| MgO | 3.62 | ≥5.0% |

| Fe2 O3 | 2.67 | - |

| SO3 | 2.60 | ≥2.8% |

| L.O.I | 1.59 | ≥4.0% |

| Main compounds | ||

| C3 S | 33.37 | - |

| C2 S | 35.92 | - |

| C3 A | 11.09 | - |

| C4 AF | 8.12 | - |

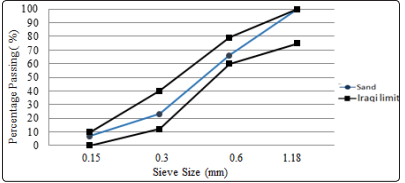

Sand: Natural river sand used as a fine aggregate supplied from Kanhash site (Nineveh/Iraq) with a specific gravity of 2.62. The grading limits according to IQS: 5/1984 are given in Figure 1 [12].

Figure 1: Grading of Sand

Fiber: Straight shape micro-polypropylene fiber with 12 mm length was used; their characteristics are presented in Table 3.

Table 3: Characteristics of Polypropylene Fiber| Fiber properties | Quantity |

|---|---|

| Average fiber length (mm) | 12 |

| Diameter (mm) | 0.018 |

| Tensile strength (MPa) | 137-689 |

| Young's Modulus (GPa) | 3.4-4.8 |

| Toughness (GPa) | 8.82 |

| Elongation (%) | 25 -40 |

| Specific gravity | 0.9 |

| Melting point ( °C) | 160 |

Superplasticizer: High-range water-reducing (HRWR) admixtures (superplasticizers) were used conformance to ASTM C494, Type F [13].

Water: Tap water was used for mortar mixtures as a medium for cement hydration.Cement mortar mix proportion is seen in Table 4. Mortar mixes were prepared using water-cement ratio of 0.40. The amount of Superplasticizer varied from 1.5% to 2.2% by weight of binder content to maintain suitable flowability for all the mixes. The mix design of the reference mix (PP-0%) was carried out by the trial mix to achieve the criteria of mortar. Polypropylene fibers were included to the mixes at volumetric fraction of 0.2%, 0.4%, 0.6% and 0.8% in the preparation of mixes (PP-0.2% to PP-0.8%).

After completion of mixing materials, the flow test for the mixes was performed with a desirable flow of 100% to 130%. Three cube specimens (50x50x50 mm) have been used for each mix to test the density and compressive strength. The cube specimens were left in the mounds for 24h at 20 °C. After demoulding, the specimens were transferred into the water for curing until the age of test. The compressive strength test was done immediately after determining the density test specimens. The flexural strength of the specimens (40x40x160 mm) was conducted and cylinders were cast (100 mm in diameter and 200 mm in height) to determine the splitting tensile strength (indirect tensile strength) and tested at age 28 days [14-18].

Table 4: Fiber-Mortar Mix Proportions| Index | Cement Kg/m3 | Sand Kg/m3 | SP (%) | W/C | Polypropylene Fiber (%) | Flow (%) |

|---|---|---|---|---|---|---|

| PP-0% | 585 | 1462 | 1.5 | 0.40 | - | 130 |

| PP-0.2% | 585 | 1462 | 1.5 | 0.40 | 0.2 | 120 |

| PP-0.4% | 585 | 1462 | 1.8 | 0.40 | 0.4 | 110 |

| PP-0.4% | 585 | 1462 | 2.0 | 0.40 | 0.6 | 110 |

| PP-0.8% | 585 | 1462 | 2.2 | 0.40 | 0.8 | 100 |

It is clear from Table 4, that the presence of polypropylene fiber in mortar mixes reduces the flowability therefore; increasing amounts of high range water reducer admixture (Superplasticizer) were needed along fiber volume fraction increase. Flowability of mortar mixes varied between 130-100%, the flow was about 130% for reference mix (PP-0%), and reduced with increase of polypropylene fibers. Thus, the use of 0.8% of polypropylene fibers gave up most reduction in the flow to 100%, this reduction in flow was confirmed by the majority of reinforced concrete researches. Noticed that the addition of polypropylene fibers in mortar presents a large reduction in the workability and the use of a Superplasticizer is a necessity [19-20].

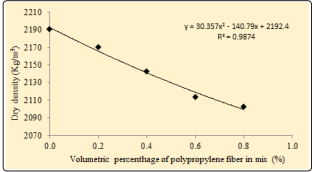

From the results show in table 5, it can be noticed that the addition of polypropylene fibers led to a reduction in the mass of the hardened mortar, which was an expected result due to the low specific gravity of fiber which reduce the overall density of mortar, therefore the higher volume fraction 0.8% PP fiber revealed 4% reduction in density. Show incorporated polypropylene fibers in cement mortars with the aim of reinforcing the composite material reducing its weight [21].

Table 5: Mechanical Properties of Mortar Mixes| Index | Dry Density (Kg/m3 ) 28-day 28-day | Compressive strength (MPa) 7-day | Compressive strength (MPa) 28-day | Compressive strength (MPa) 56-day | Flexural strength(MPa) 28-day | Split tensile strength (MPa) 28-day |

|---|---|---|---|---|---|---|

| PP-0% | 2190 | 42.3 | 50.6 | 55.4 | 9.0 | 3.1 |

| PP-0.2% | 2185 | 46.8 | 52.5 | 58.2 | 10.1 | 3.5 |

| PP-0.4% | 2142 | 45.5 | 54.8 | 56.4 | 9.8 | 3.5 |

| PP-0.6% | 2113 | 44.0 | 55.8 | 57.7 | 9.6 | 3.1 |

| PP-0.8% | 2102 | 40.4 | 51.0 | 56.8 | 9.4 | 3.0 |

Figure 2: Relation between Fiber Content and Saturated Surface Dry Density at 28 Days

Although the influence of the PP fibers on the mechanical properties of mortar have been thoroughly investigated by several studies [2, 20, 21], an analysis of the obtained results for the main mechanical properties was necessary due to their effects by the mechanical and geometrical properties. As well as; the dosage of fibers, which interacted with the behaviour of high performance mortar. Table 4 shows the mechanical properties obtained for all mortar mixes reinforced with polypropylene fiber.

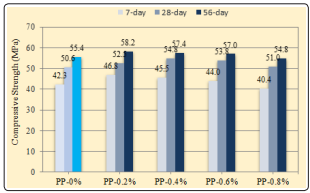

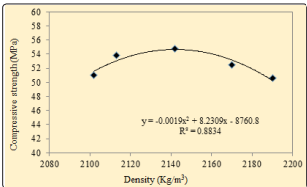

In all mortar mixes the trend of the results led to an improvement in mechanical properties of HPM when low dosages of polypropylene fiber were added. In the case of compressive strength, the results show increases in compressive strength till 0.6% of PP fiber as volumetric fraction of the mix, but beyond this fraction, compressive strength reduces clearly, this behavior related with the fact of less workable material those compaction was. As well as an excessively large amount of polypropylene fibers may be affected with the continuity and prevented the material from generating a coherent matrix. This fact is consistent with the conclusion of who stated that discontinuities along the mortar structure would lead to a decrease in mechanical strengths. Figure 3, show the increase of fiber from 0% to 0.2% increases the compressive strength at 7, 28 and 56 days by about (4-10%) in spite of the decrease in density. Figure 4 illustrates the relation of compressive strength and density for the fiber reinforced high performance mortar at 28 days [22-23].

Figure 3: Relation between Fiber Content and Compressive Strength

Figure 4: Relation between and Compressive strength and density at 28 Days.

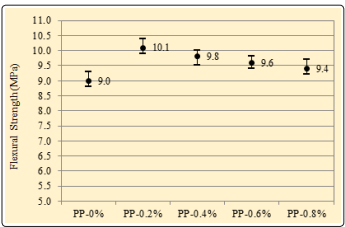

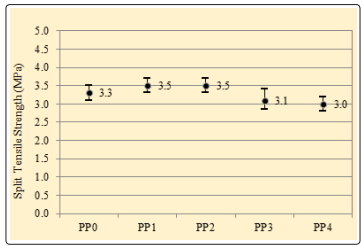

For the PP-0.2% mortar mix incorporating with 0.2% fiber volumetric fraction shows increase of 12% in the flexural strength and 13% in splitting tensile strength this increasing in strengths is compatible with the compressive strength increase, and also, Figures 5&6 illustrates the increase of the flexural strength of 0.2 % volumetric fraction of polypropylene fiber in the mix and beyond this percentage the decrease in strengths. This related to the lowest dosage used of fiber the matrix causes a reduction of the amount of larger pores and increase in the small ones and this led to a more compact material, thus explaining the lower water vapour permeability and the higher mechanical strengths. On the other hand, the highest amount of fiber produced a less compact mortar, which is in agreement with the lower density, the higher air content, the larger water vapour permeability and the lower mechanical strengths [24].

Figure 5: Relation between Fiber Content and Flexural Strength

Figure 6: Relation between Fiber Content and Direct Tensile Strength

The experimental study on the mortar reinforced with various volume fractions of polypropylene fibers reveals the following conclusions: