Author(s): Maged Naser* and Lamia H Shehata

Due to the world’s regular demand for rice as a predominant meals crop, the quantity of rice straw produced pressurizing the waste management techniques of the countries. Rice straw is a huge waste administration trouble in rice-producing countries such as China, India, Vietnam, Indonesia, Brazil, etc. Burning rice straw on the discipline is the most preferred option for farmers to get rid of the rice straw which creates an array of environmental issues. In addition to jeopardizing the surroundings by means of emitting a great quantity of greenhouse gases (GHGs), the inappropriate utilization of rice straw and open crop burning in the discipline additionally have a tendency to lose farmers a very worthwhile by-product. Benefits can be harnessed via utilising the ample rice straw as an uncooked cloth for precious product generation. This work critiques the huge elements of the use of rice straw as an imperative supply of easy energy. The paper emphasizes some essential background knowledge, such as the chemical, and bodily houses that decide the calibre of rice straw. The specific pretreatment techniques that can make rice straw equipped for hydrogen manufacturing have additionally been discussed. The cutting-edge thermochemical and biochemical methods for changing rice straw into hydrogen are vividly presented.

Further analyzing the viability of producing hydrogen from rice straw in the context of modern agriculture turns into extra crucial. The existing assessment additionally mentioned the policies and modern state of affairs of hydrogen manufacturing globally and gives a forecast on the state of hydrogen as a clean fuel for a sustainable future

The annual amplify in world populace has resulted in a surge in energy consumption, exacerbated with the aid of the indiscriminate use of traditional fossil fuels. This has resulted in countless environmental problems such as the prevalence of extreme weather events, world warming, acid rain, and sea degree rise. As a result, there is a pressing need to advance inexperienced and renewable energy sources. Energy derived from biomass is regarded an environmentally pleasant alternative due to its green and carbon-neutral nature. rice straw, a byproduct of rice production. Following the harvesting of rice the grain is separated from the rice straw (RS), which stays as a waste or byproduct. The straw-to-paddy production ratio varies between 0.7-1.4, relying on the type and growth conditions of the rice. It is estimated that around 800-1000 million tons of RS are produced yearly worldwide, with Asia contributing almost 90% of the complete productionof 600-800 million tons [1].

The sizeable waste generated from rice harvesting poses a good sized challenge for farmers, governments, and society. While the rice straw (RS) produced can serve as a soil fertilization agent, its degradation is hampered through the presence of recalcitrant lignin in the structure. Consequently, farmers frequently resort to burning the RS in the field, ensuing in extreme harm to air quality and soil fertility. The burning of one kilogram of RS leads to the emission of 0.019-0.069 g of nitrous oxide and 0.7-4.51 g of methane [2].

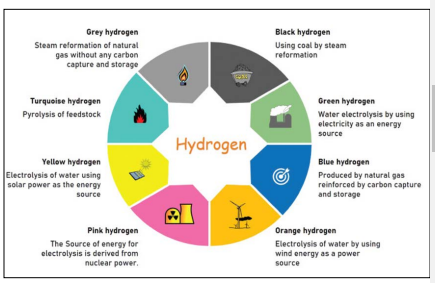

The launch of green house gases and particulate matter from RS burning has giant affects on the surroundings and human health [3]. As a choice to burning, rice straw (RS) can be processed into pellets, briquettes, and bales for energy generation. Additionally, RS can be used for agricultural purpose such as the formation of biochar, media for mushrooms, and cattle fodder and feed. Industrial functions of RS encompass the manufacturing of constructing substances such as brick, fibreboards, as properly as high-end substances such as biofilter and silica. Energy conversion of RS entails thermal conversion into syngas, electric power, and heat, anaerobic digestion into biogas and hydrogen, and fermentation into bioethanol. Presently, there is a pressing worldneed for renewable and non-polluting fuel sources. Hydrogen represents one such fuel, however 96% of it is derived from herbal fuel (48%), oil (30%), coal (18%), and water (3.9%) [4]. Given the expected decline of fossil gasoline reserves, hydrogen is more and more recognized as a possible substitute. Hydrogen has the achievable to alleviate socio-environmental problems and promote the utilization of renewable sources, such as biomass, for hydrogen production. Compared to different fuels such as coal, gasoline, and methane, hydrogen combustion can produce greater energy whilst having a decrease heating value [5]. Importantly, hydrogen combustion outcomes in the manufacturing of water as the sole by product. Moreover, due to its excessive reactivity and superior energy density in contrast to gasoline, ethanol, and methane, hydrogen can be effectively transformed into electrical energy with an effectivity exceeding 80% [6]. Hydrogen fuel is regarded a highest quality gas in contrast to conventional fuels, as it has a greater power density (120 MJ/kg) at ambient temperature and pressure [7].

The use of biomass as a substrate for hydrogen manufacturing provides the benefit of minimal greenhouse fuel emissions, owing to the carbon-neutral nature of biomass. The future of hydrogen era from biomass mostly relies upon on the improvement of much less polluting and extra environment friendly technologies. There are countless methods for hydrogen production using renewable sources such as biomass and water. Water can be used as a raw material for hydrogen production through various applied sciences such as thermochemical water splitting, photo electrolysis, bio photolysis, electrolysis, etc.

Similarly, biomass-based hydrogen manufacturing applied sciences like anaerobic digestion, aqueous phase reforming, pyrolysis, gasification, thermochemical conversion, etc. are extensively used in a number of industries [8]. Utilizing rice straw for hydrogen manufacturing provides the plausible to attain sustainable development goals (SDGs) set by way of the United Nations, such as climate action and get right of entry to to affordable and clean energy. Rice straw is one of the most cost effective biomass sources, in particular in densely populated Asian nations such as China and India [1]. Thus, harnessing this plentiful source of energy for hydrogen manufacturing should be a treasured resource.

i. houses of rice straw, consisting of its chemical composition, pretreatment strategies, manufacturing science and the challenges associated with its use for hydrogen manufacturing.

ii. challenges related with the scale-up of rice straw-based hydrogen production, including the need for research and development, infrastructure, and supply chain development.

iii. an overview of the current state of hydrogen manufacturing and the benefits of the usage of rice straw as a substrate.

iv. examines the policy and regulatory issues related with the improvement of hydrogen manufacturing technology, policies and regulations, that have an effect on the use of hydrogen for energy production, which include incentives and subsidies for renewable energy sources [9,10].

In conclusion, this paper gives a complete overview of the challenges and possibilities related with the usage of rice straw as a substrate for hydrogen production. By exploring the fundamental problems associated to rice straw-based hydrogen production, this paper pursuits to grant insights into the potential of rice straw as a sustainable and environmentally pleasant supply of energy. The findings of this overview will be beneficial for policymakers, researchers, and stakeholders in the power area to strengthen techniques for assembly the growing demand for smooth and sustainable energy.

The enormous cultivation of rice throughout the globe has resulted in a full-size abundance of rice straw, accordingly making it one of the most considerable sources of lignocellulosic waste. Rice straw manufacturing via continent wise, which surely indicates Asia is biggest producer of rice straw. The utilization of biomassderived hydrogen as an alternative for standard fuels is gaining momentum. However, the production of hydrogen from firstgeneration feedstocks such as food crops and grains possess a vast mission to the international meals supply. To overcome this challenge, a shift in the direction of non-edible plant substances is necessary. Such plant components include fermentable sugarproducing carbohydrates, which include hemicellulose and cellulose. These sugars can be conveniently transformed into hydrogen via both fermentation or chemical/enzymatic methods [8]. Rice straw possesses countless perfect residences that make it an appropriate feedstock for hydrogen production. It contains great quantities of hemicellulose and cellulose, which can be effortlessly modified into fermentable sugars. The chemical composition of rice straw is basically composed of lignin (5%- 24%), hemicellulose (19%-27%), and cellulose (32%-47%). The most ample sugar in hemicellulose is xylose (14.8-20.2%) [11]. The quality of straw exhibits massive version based totally on the geographic place and seasonal changes, and precipitation-induced leaching of alkali and alkaline chemical compounds can enhance its quality for biofuel production. The suitability of the material for hydrogen synthesis is reliant on its availability and quality.

Rice straw (RS) stands out as a specifically superb biomass feed stock owing to its low lignin content, wide spread availability, and potential for energy manufacturing [12]. Therefore, there is developing interest in investigating the attainable of rice straw as a sustainable and cost effective supply of hydrogen in the area of renewable energy. Hydrogen, as a fuel, is no longer handy in its pure structure in nature and requires manufacturing through a variety of techniques [13]. Consequently, the quest for creating renewable and sustainable strategies of hydrogen manufacturing is gaining momentum. Rice straw can be transformed to hydrogen using different techniques, such as steam methane reforming, gasification, and fermentation [14]. Steam methane reforming is a chemical technique that includes the response of methane, which is in many instances derived from natural gas, with steam to generate hydrogen and carbon dioxide. Rice straw can be transformed into methane by means of the anaerobic digestion process. During this process, microorganisms decompose the natural matter in rice straw, yielding hydrogen as a byproduct. Additionally, gasification is any other science that can be utilized to convert rice straw into hydrogen. In this process, rice straw is thermally dealt with in the absence of oxygen, resulting in the manufacturing of a combination of gases that include hydrogen. The hydrogen obtained through gasification can be used as a gas or subjected to similarly processing to generate electrical energy [15]. Although the organic method for changing rice straw into hydrogen is no longer as mature as steam methane reforming or gasification, it is desired due to its sustainable nature. Furthermore, rice straw is relatively cheaper in contrast to different biomass feedstocks, making it a low-budget supply of hydrogen. Additionally, using rice straw for hydrogen manufacturing can assist mitigate greenhouse fuel emissions. Burning or decomposing rice straw results in greenhouse gas emissions [16]. By changing rice straw into hydrogen, these emissions can be avoided. Moreover, the hydrogen produced from rice straw can be utilized as a cleanburning fuel, in addition reducing greenhouse fuel emissions. The abundance and renewability of rice straw, mixed with its versatility in conversion processes, make it a promising choice to ordinary techniques of hydrogen manufacturing. As the pursuit of sustainable and renewable energy sources persists, rice straw warrants further exploration as an achievable alternative.

Lignocellulosic biomass is anticipated to change petroleum as the most probably renewable alternative. Rice straw is a lignocellulosic material containing majorly lignin, cellulose, and hemicellulose. A heterogeneous combination of carbohydrate polymers fabricates rice straw. Lignin firmly holds the cellulose and hemicellulose and shields them from enzymatic degradation. The manner of bio hydrogen manufacturing from rice straw entails numerous steps, including pretreatment, hydrolysis, fermentation, and hydrogen production. Pretreatment of rice straw is essential to smash down the complicated shape of the lignocellulosic biomass and make it extra on hand to hydrolysis. Pretreatment can be accomplished via a number of methods, which includes physical, chemical, or organic methods, or an aggregate of these methods. Physical techniques encompass milling or grinding to minimize the particle size, whilst chemical techniques involve the use of acids, bases, or solvents to destroy down the biomass [15]. After pretreatment, the rice straw is subjected to hydrolysis, which breaks down the complicated sugars into easy sugars. Hydrolysis can be done through the use of enzymes or acid/base hydrolysis. Enzymatic hydrolysis includes the use of enzymes such as cellulases and hemicellulases to destroy down the cellulose and hemicellulose elements of the rice straw. Acid/base hydrolysis involves the use of acid/base to spoil down the lignocellulosic shape of the biomass. Among the pretreatment methods physical and chemical techniques are extensively used. Physical techniques contain breaking the lignocellulosic shape and reduction of biomass measurement to expand the surface area. Rice straw, an achievable biomass supply for hydrogen production, can be subjected to more than a few pretreatment methods to alter its ultrastructure and enhances biodegradability. Among the traditional methods, comminution is employed to produce lignocellulose biomass of a particular dimension vary (0.2-2 mm), ensuing in decreased cellulose crystallinity and accelerated surface area [17]. Another popular technique is steam explosion, the place the lignocellulosic biomass is dealt with at multiplied temperatures (160-260 °C) and pressures (0.69-4.83 MPa) for a short duration [14]. This procedure efficiently redistributes lignin and hydrolyses hemicellulose into sugars, accelerating the biodegradation process. The physicochemical houses of rice straw are drastically altered after steam explosion, main to greater bacterial activity. In a find out about through Zhou and colleagues, steam-exploded rice straw verified a greater abundance of Clostridium bacteria, accountable for hydrogen production, in contrast to untreated rice straw [18]. These outcomes recommend that steam explosion facilitates the disruption of the lignocellulosic shape and will increase the accessibility of cellulose for bacterial fermentation into sugars. Advantages of bodily pretreatment strategies are: (i) Simple and easy to operate: Physical pretreatment methods do no longer require any chemical or organic agents, making them easy and simple to operate; (ii) Low cost: Physical pretreatment techniques are usually less expensive in contrast to chemical and organic pretreatment methods; (iii)Improved accessibility: Physical pretreatment techniques can expand the accessibility of the lignocellulosic shape of rice straw to hydrolysis, making it less difficult to convert into easy sugars; (iv) High throughput: Physical pretreatment methods can be effortlessly scaled up, making them appropriate for large-scale production.

i. High electricity consumption: Physical pretreatment strategies can require a big quantity of energy, which can increase the value of the process;

ii. Limited selectivity: Physical pretreatment strategies are now not selective and can damage the cellulose and hemicellulose factors of the biomass, ensuing in decreased yields and decrease excellent of the final product;

iii. Formation of inhibitory compounds: Physical pretreatment techniques can end result in the formation of inhibitory compounds, such as furfural and 5-hydroxymethylfurfural (HMF), which can inhibit the growth of microorganisms during fermentation;

iv. Environmental impact: Some bodily pretreatment methods, such as thermal pretreatment, can produce greenhouse gases and different pollutants, contributing to environmental impact.

Alkaline pretreatment is a quite advantageous approach for delignification of lignocellulosic biomass, ensuing in increased porosity and surface area, and decreased cellulose crystallinity. Sodium hydroxide is the most often used base for alkaline pretreatment, even though different bases such as calcium hydroxide and potassium hydroxide can additionally be used. Sattar and coworkers observed that alkaline pretreatment was once the most environment friendly and advantageous approach for rice straw, resulting in excessive lignin, cellulose, and hemicellulose removal, as nicely as top of the line hydrogen manufacturing [19]. Acid pretreatment methods, such as sulphuric, hydrochloric, nitric, and phosphoric acid, have additionally been used for biomass pretreatment. Mechery and coworkers in contrast hydrogen manufacturing from rice straw pretreated with acid (sulphuric acid) and base (sodium hydroxide) and observed that the acid hydrolysate produced greater ranges of sugars and hydrogen than the alkaline hydrolysate [20]. Chang and coworkers stated similar results, displaying that acidic pretreatment of rice straw extended fermentable sugar and hydrogen yields in contrast to untreated rice straw [21].

Cai and coworkers in contrast two pretreatment techniques for rice straw, alkaline and electro-hydrolysis, and located that alkaline pretreatment was once gold standard in phrases of excessive lignin elimination and keeping the cellulosic structure [22]. Dong and coworkers proposed a revolutionary method for pretreating rice straw, which entails the use of alkali/urea at subzero temperatures [23]. The ensuing substances exhibited accelerated hydrogen production, making this approach specially beneficial for international locations with subzero temperatures. While pretreatment at elevated temperatures generally consequences in greater sugar and hydrogen yields, the related energy costs render the process economically unfeasible. The traditional approach of producing warmth has been supplanted through microwave-based heating, which selectively heats the substrate. Combining alkaline and microwave pretreatment has confirmed to be an efficient strategy for economically possible hydrogen manufacturing [24]. For instance, microwave-assisted alkaline pretreatment of rice straw resulted in a higher hydrogen yield in contrast to the control, most likely due to increased manufacturing of fermentable sugars springing up from the fantastic disruption of the lignocellulosic structure.

Environmental Technology & Innovation coworkers in a similar fashion observed that microwave-assisted alkaline pretreatment expanded the crystallinity index and reducing sugar contentmaterial of rice straw, which resulted in stronger hydrogen manufacturing [25].

i. Increased digestibility: Chemical pretreatment strategies can damage down the complex carbohydrates in rice straw into less complicated sugars, making it less complicated for microorganisms to digest them and produce biofuels

ii. Higher yields: Pretreatment can additionally expand the yield of biofuels through releasing greater sugars from the rice straw.

iii. Reduced toxicity: Some chemicals, such as alkali, can decrease the toxicity of rice straw by using casting off or decreasing the content of inhibitors that can restrict microbial growth.

iv. Cost-effective: Chemical pretreatment techniques are generally less steeply-priced than different strategies such as bodily or organic pretreatment.

i. Environmental concerns: Chemicals used in pretreatment, such as acids or alkalis, can be detrimental to the surroundings if now not handled properly.

ii. Safety concerns: Chemicals used in pretreatment can additionally pose a danger to human fitness if suitable safety protocols are now not followed.

iii. Formation of degradation products: Some chemical substances used in pretreatment can produce harmful degradation merchandise that can negatively have an effect on the conversion method or the environment.

iv. High energy consumption: Some pretreatment strategies can also require excessive energy input, which may want to make bigger the usual cost of the process.

In current years, organic pretreatment has emerged as a promising approach due to its quite a several advantages. It requires low funding costs, minimal energy and chemical requirements, and operates beneath moderate pretreatment conditions compared to physicochemical methods. Additionally, it does now not generate any inhibitors that may want to preclude hydrolysis and fermentation processes, as a result removing the need for detoxing procedures. However, the major dilemma of biological strategies is the quite decrease fermentation charge in contrast to different technologies. Due to excessive degradation rate of lignin by way of fungi, they are the powerful pretreatment organic agents. Sheng and coworkers stated the efficiency of Gymnopus sp. J2 for the pretreatment of rice straw and extend in hydrogen production. The pretreatment caused a loss of 17% hemicellulose and 13% hemicellulose with almost 22% lignin removal. This resulted in a 74% increase in the hydrogen manufacturing than barring pretreatment [26]. Similarly, laccase enzyme, Phenarocheate chrysosporium pretreatment additionally promoted the lignin elimination and enzyme exercise enhancement [27,28]. Recent advances in pretreatment methods have opened up new probabilities for the environment friendly conversion of rice straw into hydrogen. These methods vary from physical, chemical, to organic strategies and have proven promising results in phrases of expanded hydrogen yield and lowered energy consumption. Despite the advantages of pretreatment, the resolution of the fabulous approach generally relies upon on quite a few factors, such as the composition of the rice straw, the centered end-product, and the reachable resources. However, it is really worth noting that pretreatment has a significant impact on the financial feasibility of producing hydrogen from rice straw. Therefore, persevered lookup and development of pretreatment strategies for rice straw should lead to a least expensive and sustainable supply of hydrogen, which can contribute to lowering carbon emissions and mitigating local weather change.

The thermochemical system for hydrogen manufacturing from rice straw entails a number of steps and key components, including: Pretreatment: Rice straw is first pretreated to take away impurities and enhance its digestibility. This can be completed through physical, chemical, or organic methods. Gasification: The pretreated rice straw is then gasified in a reactor at excessive temperatures (typically between 700-1000 °C) and in the presence of a gasifying agent, such as steam or air. The gasification system converts the biomass into a syngas, which is a combination of hydrogen, carbon monoxide, carbon dioxide, and different gases. Gas cleaning: The syngas produced in the gasification method carries impurities, such as tars, particulates, and sulphur compounds, which need to be eliminated earlier than the hydrogen can be extracted.

Utilizing low-carbon hydrogen is more expensive than the usage of present applications that use hydrogen generated from fossil fuels. Carbon pricing is being applied in certain countries to minimize this disparity and inspire the use of low carbon hydrogen, nonetheless, this is insufficient to steer the internet zero emission aim by using 2050. Fortuitously, governments all over the world are launching measures to raise hydrogen demand and limit funding risks. However, the majority of these declarations have no longer but been implemented. The European Commission recommended a multiplied quota for synthetic aviation fuels in the Refuel Aviation Initiative (from a 0.7 percentage share in 2030 to 28 percentage in 2050) [29]. Apilot plant initiative for the steel and chemical sectors used to be unveiled via Germany alongside with a new countrywide hydrogen strategy. Companies will be required to pay the authorities the distinction if the EU ETS price is greater than the expenses associated with the project’s CO2 abatement [30]. The LSVA road tax, which is levied on trucks that weigh extra than 3.5 tonnes however no longer on ZEVs, was once permitted by using Switzerland [31]. The biggest ferry route in Norway will be powered by means of hydrogen, in accordance to the Norwegian authorities [31]. By 2030, Portugal’s National Hydrogen Strategy seeks to mixture 10-15 vol% hydrogen with natural gas [32]. Germany to supply investors’ self belief in the viability of projects, the government’s H2 Global initiative will provide ten-year purchase agreements on hydrogen-based items [33]

The Indian authorities declared that from 2023-2024, renewable hydrogen need to be used to meet 5% of the hydrogen demand for fertilizer manufacturing and 10% of the hydrogen demand for refineries [34]. China offers economic incentives to use hydrogen as a fuel. The gas cell electric cars pilot application awards cities that install greater than a thousand of these motors. Asia is the largest producer of rice, which helps its plausible to lead hydrogen manufacturing from a renewable and sustainable supply [35]. The position of the governments global suggests the key roles of governmental aid to create stable and predictable regulatory surroundings that helps the long-term increase of the hydrogen industry. Governmental support is vital for the advertising and adoption of hydrogen as an easy energy source. Hydrogen applied sciences are still in the early ranges of improvement and require giant funding and aid to end up economically potential and competitive with typical fossil fuel-based technologies. Government assist can take many forms, consisting of funding research and development, presenting monetary incentives and tax credits, placing regulatory requirements and policies, and investing in infrastructure.

Strategic planning and layout of a roadmap for the hydrogen manufacturing from rice straw is lots required. Some future perspectives to obtain the sustainable hydrogen manufacturing are mentioned in brief.

Utilizing rice straw for the manufacturing of hydrogen is certainly an alluring strategy to clean energy and decreasing the environmental pollution. The lignocellulosic shape of rice straw poses a principal mission for hydrogen production, and various pretreatment techniques can be used to ease cellulose publicity for environment friendly hydrogen production. It is important to word that whilst hydrogen manufacturing from rice straw is a promising approach, it is no longer a silver bullet solution. The administration of rice straw manufacturing and utilization requires a complete and built-in method involving institutional, structural, technological, and financial guidelines to tackle the root reasons of the problem [36,37].

All authors declare no conflicts of interest.

Authors have equally participated and shared every item of the work.