Author(s): Mabrouka Shahat Younis Elfargani

Value Engineering (VE) is an efficient management technology that can significantly contribute to value rise and decrease in building projects. In addition to that EV is an accepted way of recognizing and removing excessive product construction, inspection, manufacture and design, operation, repairs. The technique comprises three main stages. The first step of the study on VE is designed to schedule and organize the study of significance. Value Engineering routinely employs well-known techniques that classify the functions of the innovative product or service and thus operate at the lowest average cost of performance. Value engineering relies on the lowest marginal feature efficiency. It enables waste, time, and unnecessary expenses to be eliminated or minimized that increases customer loyalty. The second step consists of several phases: knowledge phase, research purposes phase, innovative phase, assessment phase, and initial phase. The principal components of value engineering study are value analysis. Value analysis. The two steps and actions function sequentially. This series of approaches to the VE research goals will lead to a logical and organized process flow. The third step is postal analysis. It seeks to ensure that the acceptance criteria are applied to change the research of significance in the course of study

operations. The second process consists of five phases: information phase, purpose analysis phase, creative phase, evaluation phase, and introduction phase. Value analysis is the main component of Value Engineering Research. Sequentially both stages and measures work. The rational and structured process flow is anticipated to help with this sequence of the approach to reach the VE research goals. The postal study is the third phase. It is intended to ensure the execution of the agreed guidelines to modify the important study during study operations. In the study, the values engineering principles are applied and value engineering practices in this project are defined by the study of the constructor project.

Value engineering is a methodology that employs an innovative feature problem-solving approach, providing the necessary project output and at the same time minimizing costs. The conventional cost-cutting strategies should not be correlated with it [1]. It goes further than cost reduction through a wider mechanism that combines high-quality and practical ways of managing building work to ensure the best value [2]. It can be practiced at all stages of design, such as pre-building, construction, and post-building.

Performance VE usually benefits from project costs savings by eliminating additional costs, demonstrating project efficiency, saving time, greater comprehension of project objectives, and increasing project value [2]. Improving the value of building infrastructure will have a positive effect on a country's economy. Thereby, VE is the most suitable technique for regulating value in building projects, given that other techniques are focused instead of value on time and efficiency. However, many scientists argue that VE is a systemic way of increasing the valuation of commodities, products, and services by doing an aim study.

A large number of highway projects which fulfill the EV objectives, are completed, and do not surpass scheduled costs, must be taken care of to achieve those objectives. This can be helped by a performance-based EV adapted for public work applications [3]. Project management is also required that defines and balances the complexity of the project effectively with the scheduling and costs. Besides, project managers need to consider and analyze a wide range of project alternatives with significant changes in scope, timing, and cost.

In this regard, Value Engineering tends to help a project to fulfill the cost efficiency requirement of a customer within a short timeframe [4]. It is important to be aware that VE's tools for building, particularly public works, should concentrate more on the project scale, as the key problem of this aspect is the creation of projects in public works [5]. The VE thesis examines how the situation can be improved. The approach to analytical and enhance value in a product, facilities design, system service is practical, systemic and team [6]. It provides a highly effective way to solve and reduce costs while enhancing efficiency and results [7]. By producing many new potential options, value engineering studies also included a calculated expense, schedule, and range balance. This, though, requires a committed technical team motivated and directed by such an effective mechanism in collaboration with project stakeholders [5, 8]. The key aims of this paper are to recommend the successful assessment of public projects based on the VE technique and to resume the advantages of the approach proposed.

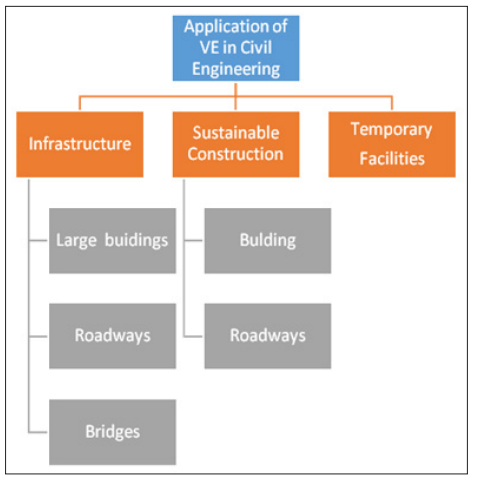

For instance, the following studies were conducted on the proper planning of a VE [9]. By developing several creative alternatives, value engineering studies can have calculated the value of expense, preparation, and distance. In partnership with project partners, this includes, therefore, a committed and driven team of professionals. It is mostly aimed at proposing a success assessment based on the VE technique for public initiatives and summarising the advantages of the proposed approach. Figure. 1, presents areas of application of VE in the civil engineering field.

Figure 1: Areas of Application of VE in Civil Engineering [9].

A large number of existing studies in the broader literature have examined the possibility of utilizing EVs especially highway projects [6]. There are typically some reasons for opposing infrastructure improvements. However, project execution cannot be delivered in a fair period and, ultimately, expenses do not meet their budget limits. The author claims that the approach of EV can allow one to find ways to improve solutions by managing costs, schedules, and reach through the generation of creative solutions. Besides that, a contracture project was found to save substantially on costs and boost project efficiency by using the right benefit engineering procedure at the appropriate time. The paper summarizes the benefits and effectiveness of the value engineering methodology along with recommendations.

There exists a considerable body of literature on value engineering (VE) and sustainable construction (SC) [5]. In the modern construction environment, sustainability and increased value are critical factors. This will enhance the value of a building project in the integration of sustainability and value engineering (VE). Therefore, this analysis was aimed at creating a structure to include VE and sustainable principles to enhance project values in the building industry in Sri Lanka. The research was based on both quantitative and qualitative methods. Moreover, the survey administered as part of the study conducted a 68.9 percent response rate, and collected data were analyzed using the Relative Importance Index (RII).

A more comprehensive description can be found in Value Engineering (VE) with Drain covers (DC) is used to act as a bridge for the limited discharge [10]. For covers, pipe, or box kind, there are two kinds. The major issues contributing to the noticeable need to cover drainage include the use of the land occupied by drainage for access or other purposes and low soil stabilization leading to bank collapse, in the least, to mitigate the adverse consequences of a contaminated drain, particularly close to residential areas. DC has multiple environmental impacts. VE is the main objective of this analysis to understand the environmental impact of DC. The technique Life Cycle Cost (LCC) is often used to compare two drain alternatives. There are drains on the surfaces. The results suggest that drainage covers are the perfect solution to the climate.

Studies of value engineering (VE) are well documented, it is also well acknowledged that irrigation water shortage is also a problem at the Canal Tail-end (CT) [11]. To solve this problem, this paper uses the value engineering (VE) technique. VE approach involves gathering water scarcity knowledge at CT, examining canal features, designing innovative ideas, assessing creative ideas based on requirements for the assessment, obtaining a shortlist of alternative value, and developing potential alternatives using Life Cycle Cost (LCC) and Net Present Value (NPV). The findings of the research demonstrate that the VE technique is an instrument for problem-solving that helps identify solutions that rely on the basic feature of the process.

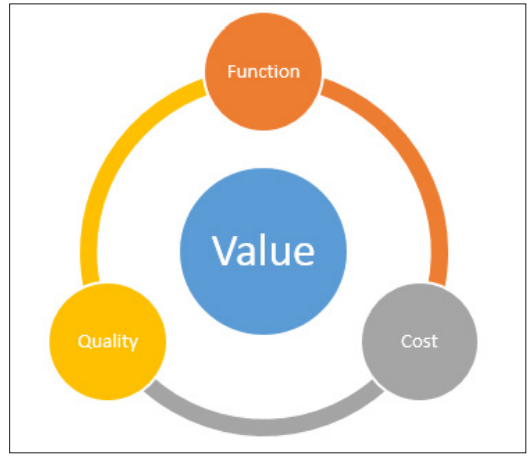

This has also been explored in prior studies by Khodeir and El, [12]. Cost overruns are a key concern in contracture projects. Value Methodology (VE), a successful solution, is a suggested technique to alleviate this challenge. Thus, this document's primary purpose is to research the role of the value technique, with particular regard to the residential projects of Egypt, in controlling overrun costs. The fundamentals of project expense implementation have been examined in the literature. A qualitative review was also carried out of case studies. The results of this article emphasized that it is possible to achieve 15% to 40% savings on overall project costs by implementing performance Value Methodology (VE). The foundations of value analysis (VA), and value engineering (VE) have to be built on the value methodology. Figure. 2, shows concepts associated with value engineering. In summary, the value methodology. Value analysis is a thought method focused on the identification of and elimination of all excessive costs while ensuring all forms of quality in all industries, constructions, or services, or anywhere the dollar is invested.

Figure 2: Concepts Associated with Value Engineering [12].

This was successfully established as described by Park et al., [1]. Value engineering is an effective administration strategy that offers advantages and increases the value of projects. However, the production of concepts during the VE workshop requires time and often depends on VE's expertise, considering the clever and negative past evidence and free-thinking techniques. While different studies have created database management technology solutions to circumvent these restrictions, it is still considered that the concept production process is a field for improvement. This study suggests building information modeling BIM-based VE to able the systematic retrieval of past VE data, and efficient generation of new ideas. Interim results present that the techniques system has a high potential to enhance VE research efficiency.

This section presents a review of recent literature [13]. The construction project's key goal is value engineering and value study of the component of the air suspension system without compromising product efficiency and consistency. The new rear spring bracket model is more expensive and weighable. The described value engineering as an efficient method to refinish the current product design against the objective of developing a new product with stress evaluation and consequent displacement is taken into account in several ways. Value innovation for new materials used in the development of products has been shown to have a beneficial effect on weight reduction, which does not affect project costs and efficiency. Value engineering related to new and used materials, which does not affect project expense and efficiency, but has had beneficial effects on weight loss. It was determined that a project would save a considerable amount by using the value engineering method right now and increase the project's efficiency. The project outlines the importance of engineering methodology's advantages and efficacy.

This section will define the term Value Engineering (VE). Moreover, VE is a management approach aimed at achieving the best practical balance between product, project, process, or service costs, efficiency, and performance. In particular, value engineering is an effective problem-solving technique capable of reducing costs while retaining or improving quality and efficiency criteria. Value engineering will indeed enhance decision-making, leading to optimum owner fund investment thus meeting the requisite efficiency and functionality. The effectiveness of VE is dependent on the ability to find ways to reduce excessive expense while maintaining efficiency, reliability, performance, and other main variables that match customers' requirements or achieve them. A structured analysis of functions to meet users' needs by applying innovation, with a premium product at the lowest life-cycle rate.

In the estimation of expense and/or employment opportunities the value engineering procedure can be used. This improvement can be achieved concerning financial characteristics and/or other analytical concerns such as performance, timing, environmental impact, and stability [14]. Increasing the value of qualitative projects and services through progress and enhancement of total cost reductions without sacrificing the requisites is possible if we apply Value Engineering Curriculum Engineering in results to cut costs and development and improve about 5% and 15%. VE system can be utilized where cost and utilized enhancements are predicted [14]. This improved financial capabilities and/or other analytical problems, including performance, planning, climate impact, and stability, can be identified [15]. Improving the quality projects and services by increasing their value by improving the overall decrease in costs by developing them without meeting the required requirements is possible if we apply Value Engineering to curriculum engineering in results, to lower costs and developments and improve them by 5% to 15% [14].

Value Analysis (VA), Value Engineering (VE), and Value Management (VM) are the principle of a single administrative method tagged to figure out specific solutions and minimize the advantage of quality in cost. Specialists in the field merit decided upon the conventions [5].

AV is called Value Analysis (VA): A research on current projects or goods that are used aims to boost their efficiency and eliminate the added costs.

VE is designed to enhance the quality and minimize the finances of construction projects and applied during project ideas or after completion of public perception.

A detailed idea of how programs are managed and how value analyses and follow-ups are set up such that this phase has a workshop for value engineering or value research. In this work, all these terms and terminology are used according to the meaning, regardless of certain technical names, but we are referring mostly to "Value Engineering," as this is the vernacular term. Performance/ Functionality (Functionality) The primary objective of the life of the item implies functionality or utility engineering, whether the feature is good or service or not. This work explains the success of the thing that has been performed, making it a significant thing. Expression of the role of value engineering studies with two words: term, verb, and alternatives need to be compared and the expense variant facilitated, for example, the weight already shown by the post-column construction of pregnancy indicates the operation or the name of observable units.

Many individuals assume meaning and price to be interchangeable, articulate themselves, and this is one criterion contrary to the right price Value such as quality and time value does not signify the same for all, for instance, the value of a piece of land next to home, which is significantly higher than the amount of land you have to expand. The special value affected by certain factors like time, time, supply, and demand conditions is a high value for everyone [14]. However, if price receivable is lower, the value or service of a good may be charged because, in the customer's view, the amount that can be remitted for the alternative price contributes to the same function and serves the same aim from a customer's viewpoint, for example, using an electric lamp for illumination to a specific luminescent level (LUX).

The value management approach can improve consumer trust and offer value for the investment by a company in either market or economic context, according to research carried out by SAVE. In items and sectors such as companies and manufacturing, architecture, transport, the government, healthcare, and environmental engineering, practitioners are applying the technique for value management [16]. They also found that the value management approach easily saves 30% of the total expense for the production of a good, the construction of a project, or the provision of a service. The return on expenditure from implementation by public and private organizations. The estimated return on investment from the implementation of value management systems by private and public companies is 10 to 1. That means $10 in net saving returns for each dollar spent in the value studies, including the time and costs for implementing them.

The technique of EV is a structured mechanism implementing the work schedule. There are several stages of the Work Schedule. In the Classroom, five distinct stages are followed by the VE technique (Job Plan) used by the VE team. Briefly, these phases can be followed:

The VE team receives as much as possible information on the project design, context, requirements, and costs of projects. The team analyses and classifies relatively high-cost environments for the structures and sub-systems. In the knowledge process, cost and energy models from cost data compiled before the workshop started are also created. These models are revised based on input obtained at the presentation by the designer [14].

The VE team uses a dynamic community interaction method to find possible solutions to perform the framework or sub-system work. Functional review forces a wider and better interpretation of the project by stimulating intensive dialogue and forcing the team to look at issues that may not otherwise have been taken into account. In the innovative phase VE team tests ideas created.

The team screens and evaluates the ideas produced during the speculative/creative process. For more studies are chosen the proposals showing the best potential for cost reduction and project development. In the innovative phase VE team tests ideas created. The team from VE classifies the concepts. Items that are insignificant or worthy of further analysis are not taken into account; the ideas which reflect the greatest cost-saving and enhancement potential have been created.

To endorse the suggestions as systematic VE plans, the VE committee analyses the concepts chosen and makes explanations, drawings, and life cycle cost estimates. Any designated concept is extended to a workable approach during the production process of the VE analysis. The architecture, asset, and lifecycle cost comparisons are suggested and the benefits and inconveniences of the proposed guidelines are analyzed descriptively [2].

Systematic implementations of known techniques that recognize product or service functions, determine the value of those functions and execute the appropriate functions at the lowest overall expense. To define connections- ships that add meaning, VE uses logical reasoning (a singular "how' – "why" interrogation technique) and analysis of functions [10]. The methods of tests and process analysis were thought to represent a quantitative system close to the scientific method. The method uses model construction as the basis for predictive relations to define hypotheses. The following minimum basic features should apply to any VE technique. Description of the objectives and scope of the project in enough detail to assure the direction of the study. Planned to complete each step of the VE with the expected timing of the VE analysis. Moreover, Set the goal data to formally present the outcomes of the initiative. The worth analysis consists of six VE approach steps as illustrated in table 1.

|

Num. |

Phase |

Description |

|

1 |

Information |

The project construction criteria and the study objectives are defined and reviewed during this phase. |

|

2 |

Function Analysis |

The functions of two-word, active verb / observable, or noun roles have been established during this process. These tasks are evaluated and analyzed to evaluate the priorities of the project. |

|

3 |

Creative |

Creative approaches are used to carry out the project work by defining other processes. |

|

4 |

Evaluation |

A performance assessment process is followed to choose those ideas which provide the potential for value enhancement |

|

5 |

Development |

Development of chosen proposals with adequate documentation to decide

|

|

6 |

Presentation |

Development of a report that documents and coveys the adequacy of the alternatives. |

Role of Value Engineering

The Value Engineering (VE) manages the whole cost of the life cycle, not just that of the current plan, it gives a comprehensive evaluation of the whole structures and operations of a product, rather than only a single-phase or components [17]. If the expense for the life cycle is already known from similar/identical projects, potential earnings can be assessed; assessments are taken with more certainty due to the quality of available evidence and the specification of the success criterion. Both alternatives, new concepts, and contingency plans are included. In addition to the specification and construction project improvements that can be developed and that are apparent in savings of time and costs, the ultimate benefit of Technology (VE) is to achieve optimum performance outcomes. Appropriate execution can detect problems during the early project stages.

Value Engineering (VE) grants objective assessments to management and promotes concept or brief description information and associated features and cost of resources. If Value Engineering (VE) is applied properly, cost savings of 10-15% of the project cost can be achieved. It is important to understand how to implement Value Engineering (VE) for a particular project as early as involved to reach these advantages. The cost of the project is much lower as planning and construction processes have not gone through, making it easy to estimate and restrict from the outset, so the possibility of reducing the maximum costs at these early phases of the project development would be much greater. Besides that, time and cost reduction, productivity enhancement, mitigation of non-essential duplication of money, precise decision-making, and coordination improvement are the main targets to be accomplished without abandoning performance improvement. The option should yield reliable and optimal solutions, thus reducing the uncertainty of values and costs. If there is no extra expense is to increase the efficiency or capacity to execute the tasks, the benefit would be minimized.

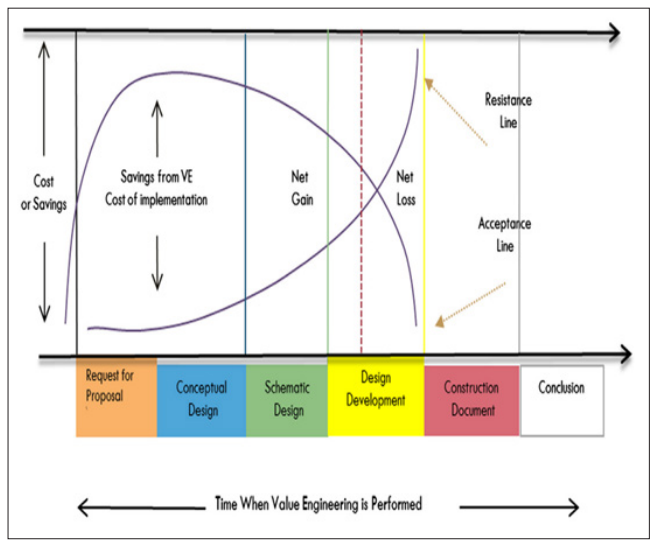

The measure of the user’s value can be obtained by three parts: quality, function, and cost as presented in Figure. 3. Furthermore, Value Engineering (VE) can be utilized due to the early stages of the project as shown in Figure. 4. The elaboration of these parts is written by the following equation.

Value = (function + Quality) (1)

Value = (Performance / Cost) (2)

Noted that the Function means the specific work that the design can be performed for each part. On the other hand, quality refers to the needs of the owner or user desires, and expectations. Moreover, the Cost highlighted the cost of the project life cycle.

Figure 3: The Value Engineering Equation

Figure 4: The Phases of the Project and their Relation to the Expected Savings by SAVE

Throughout each point of the project development, the VE studies may be carried out. But it is well aware that if it is extended during the phases illustrated in figure 4. There will be space for a higher return on investment. During the early stages of the project, value engineering can be used. This would be more helpful if it is implemented to improve and enhance performance even before funding decisions, system/design approvals.

Value engineering is unique and highly sophisticated management practice, combines technology and economy. It needs several technical divisions and business segments, a broad range of business know-how, and technological details. Therefore, we shall plan for the appropriate departments to participate in the process of the value engineering application in compliance with device engineering requirements. And in this manner will the desired result be achieved. Under the requirements of quality assurance and at the lowest cost we will obtain the required benefit. In every stage of a project design growth period, value engineering can be implemented. In the early stage of development and design concepts, however, the greatest advantage and resources are generally gained. Over the life of the project, VE may be used more than once. Early VE feature enables to start the project and prolonged exposure allows to filter the course of the project based on new or evolving facts.

It is critical that elements of the architecture are usable and compared to the specifications of the owner. The implementation of value engineering methodologies will benefit from the efficiency and expense of highways and other projects in the public works field. The VE approach specifically allows for an analysis of project goals and attributes, which in turn reflects on the advancement of value studies alternatives. To sum up, the Value Engineering (VE’s) capacity to improve the productivity of the construction sector could never be removed from the clear advantages that VE introduced in the construction industry's ventures. The right judgment is, for example, one of the key tasks during the preparation phase which should be used in the extensive value management capabilities. Besides, the proper development of decisions in preparation would improve the benefit and productivity of projects relevant to the construction industry in the implementation process.